Shafted Screw Conveyors

Durable shafted screw conveyors for bulk material handling

Ideal for powders, grains, cement & more with reliable long-distance performance.

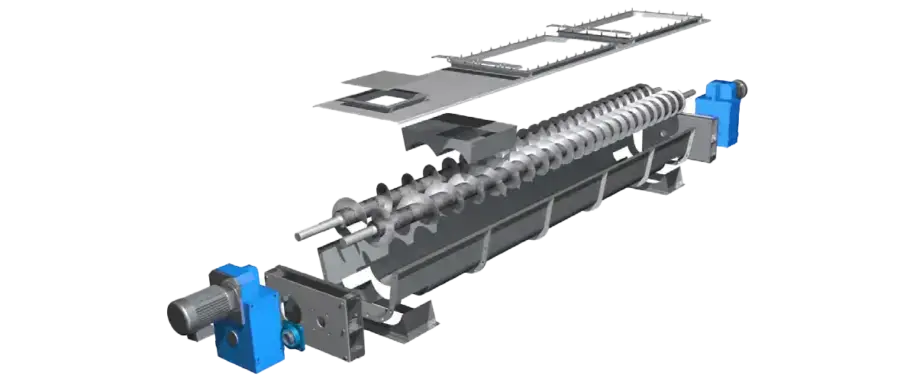

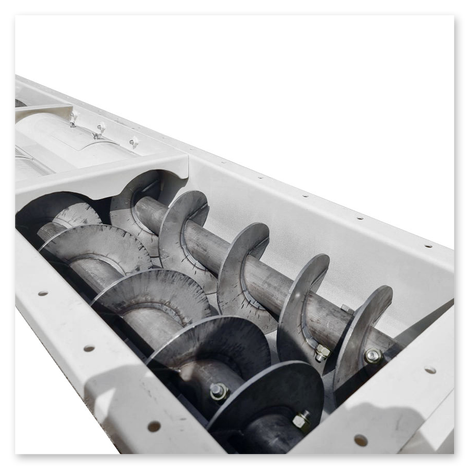

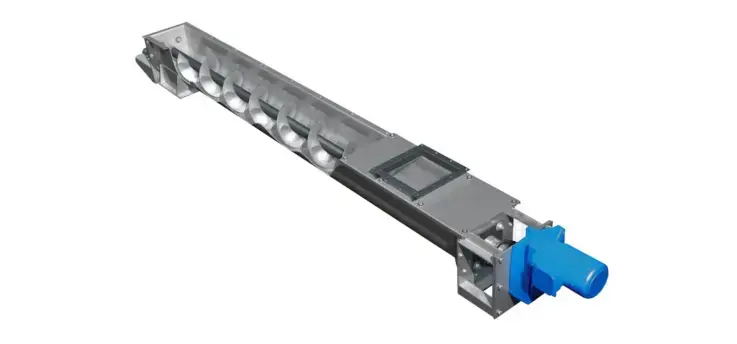

A shafted screw conveyor features a helical screw flight welded around a central shaft and enclosed within a trough or tubular housing. As the shaft rotates, the screw efficiently conveys material along the conveyor’s length. This design is widely applied in bulk material handling, capable of transporting a broad range of dry to semi-fluid products, including grains, powders, cement, aggregates, chemicals, and certain types of sludge.

þ Carbon Steel and Stainless Steel

þ Flight Configurations Available For Mixing And Chopping

þ Jacketed Housings Available for Cooling/Heating

þ Dry To Semi-Fluid Materials

þ Cost-Effective Compared to Other Conveyors

þ Totally Enclosed For Corrosive/Hazardous Environments

Shafted Screw Conveyor Overview

Shafted Screw Conveyors feature a solid or tubular shaft that runs through the center of the screw flights. The shafted design aids in keeping the auger above the trough, resulting in less friction that typically leads to wear and metal detachment from physical contact and speed of rotation.

Advantages of Shafted Screw Conveyors

- Ideal For Handling Dry To Semi-Fluid Materials

- Capacity to Transfer Free-Flowing To Sluggish Powders and Ingredients

- Less Maintenance - Shafted Screw Conveyors Do Not Require Liners on the Inside of the Trough

- Cost-Effective When Compared To Other Conveying Devices Such As Belt, Pneumatic Or Aero-Mechanical Conveyors

- Efficiently Distributes Bulk Materials To Various Locations Using Multiple Inlet And Discharge Points

- Dust Free - Totally Enclosed For Corrosive Or Hazardous Environments

- Can Typically Be Longer Compared to Shaftless Screw Conveyors

- Can Run at Higher RPM Due to Reduced Wear on the Bottom Liner