Bulk Material Handling Equipment

Bulk Material Handling Equipment and Systems Supplier

Leading bulk material handling equipment supplier offering industrial processing equipment for bulk solids handling

CMT Process Solutions is dedicated to being your trusted partner in bulk material handling and bulk processing equipment for industrial and manufacturing environments. We understand that reliable bulk solids handling is essential to every production line, which is why our engineering team designs systems with the highest-quality equipment available today.

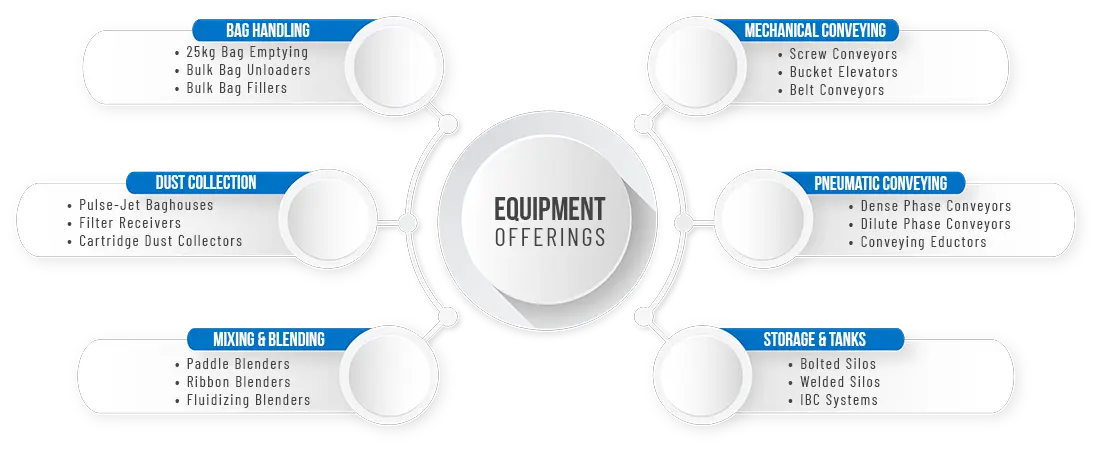

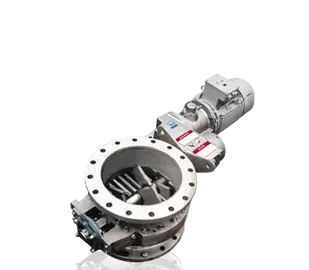

With more than 30 years of expertise in automated bulk material handling, our specialists work closely with you to create solutions tailored to your plant’s unique requirements. Our portfolio spans every stage of bulk material processing, including dust collection and air pollution control, precision feeders, instrumentation and control systems, mechanical conveyors, mixers and blenders, bulk bag unloaders, pneumatic conveying systems, screening and separation technologies, size and volume reduction equipment, silo systems and tanks, as well as valves, weighing systems, and scales.

At CMT, we go beyond simply supplying equipment—we deliver custom-engineered systems that enhance efficiency, improve reliability, and support long-term growth for your operation.

Process Equipment

Understanding the Bulk Material Handling Engineering Design Process

Selecting the right Bulk Solids Handling Equipment is critical to the performance of any bulk material handling system. Choosing an unsuitable component for a given application can compromise both process efficiency and end-product quality. Effective engineering design requires a thorough understanding of the physical and chemical properties of the materials being processed. Factors such as material characteristics, plant moisture levels, temperature conditions, and bulk density all play a vital role in determining flow behavior and overall system performance.

With more than 30 years of experience handling a wide range of powders and bulk solids, CMT Process Solutions combines technical expertise with proven industry knowledge to deliver the most efficient equipment for your application. Our team works closely with you to evaluate your material’s unique properties and recommend the optimal processing equipment to ensure reliable, consistent, and high-quality results.

The 5 Factors to Consider When selecting Bulk Material Handling Equipment

1) Capacity

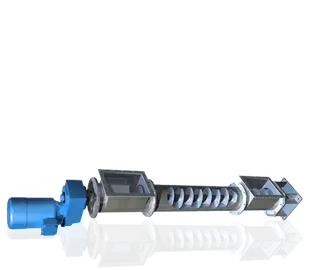

The first consideration in selecting processing equipment is capacity. Different conveyor types are designed to achieve different throughput rates. For example, if your application requires moving large volumes of material per hour, a belt conveyor may be the most effective solution. Conversely, if you need to unload over 30 tons of material per hour from 50 lb sacks, an automated system such as the LaborSave Automatic Sack Emptying System will significantly outperform a manual bag dump station. The same principle applies across equipment categories, including filling, unloading, and dust collection.

2) Distance

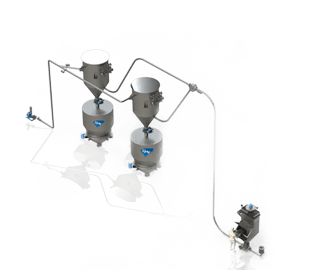

The conveying distance plays a critical role in equipment selection. For long-distance transfer, pneumatic conveying systems and belt conveyors are typically the most efficient options. For shorter distances, a wider range of technologies—such as screw conveyors, aeromechanical conveyors, and flexible screw conveyors—may be considered. At CMT, our experts evaluate your layout and operational requirements to recommend the most efficient solution.

3) Elevation

The angle of conveyance impacts system design. For vertical transfer at a 90° angle, bucket elevators are generally the most effective choice. For inclined conveying or intermediate angles, other solutions—such as vertical screw conveyors, flexible screw conveyors, or aeromechanical conveyors—may provide superior performance depending on the application.

4) Material Characteristics

The behavior of bulk solids within a hopper, vessel, or conveyor system depends heavily on their physical and chemical properties. Key characteristics include flowability, abrasiveness, friability, particle size, and sensitivity to moisture or oxidation. Materials are typically classified as free-flowing—retaining their condition under pressure—or cohesive, which may deform and compact, reducing flow quality. External factors such as moisture content, temperature, particle size, and storage duration can further influence performance. Proper evaluation of these factors ensures optimal equipment selection and long-term reliability.

5) Processing Requirements

Every process has unique engineering requirements that must be considered to maximize equipment performance. While multiple technologies may achieve similar tasks, some provide added efficiency and versatility. For example, screw conveyors can perform additional functions such as heating, cooling, or mixing during transfer, reducing the need for separate equipment. Our team at CMT works alongside you to design cost-effective, automated systems that optimize both performance and investment.