Super Sack Baler

Bulk Bag Baler Compactor for Easy Super Sack Recycling and Disposal

Automatically Roll, Compact, and Shrink Wrap 6-8 Bulk Bags in Minutes

CMT provides a Super Sack Baler Compactor that makes FIBC Bulk Bag Disposal and Industrial Recycling easier than ever. Not only can this unique baler compactor compact 7-10 super sacks into a 2' x 1' Bale in a matter of minutes, but it can also compact a variety of Films, Cardboard packaging, Plastic Foam Packaging, Paper, Plastic Foams, Fleece Materials, and more! No more dusty bulk bags laying around taking up valuable factory space. Our baler compactor has been engineered with wheels to make it mobile, so you can save valuable time, space, and effort by disposing of your recycling materials at the bulk bag unloading station.

The experts at CMT will work with you for a complete bag handling solution. Whether you need a system to unload bulk bags (see Bulk Bag Unloaders) or 50 lb bags (See Manual Bag Dump Stations or the Fully Automated LaborSave Debagging Machine), we will ensure the optimal solution to discharge and dispose yours bags in the most efficient manner.

Compacts 6-8 Super Sacks Per Bale

Decrease Labor / Increase Sanitation

Increase Valuable Factory Space

Advanced Safety Features

1'x2' Bales Allow for Easy Handling

Integrate with Unloading Systems

Features and Advantages

The Super Sack Baler Compactor provides an efficient solution for reclaiming valuable warehouse space by compacting packaging waste and industrial recycling materials. It automatically compresses and rolls super sacks into dense, manageable bales, significantly streamlining waste handling processes.

Engineered with a compact, mobile design, the unit integrates seamlessly into existing plant layouts without taking up excessive floor space. Beyond optimizing space utilization, it also enhances hygiene and sanitation within warehouse and factory environments.

Built with heavy-duty materials for long-lasting performance, the compactor includes advanced safety features to ensure operator protection during use. Its robust design not only delivers reliable operation but also drives substantial cost savings in labor, storage, and transportation.

Proudly Serving All Industries

Our Super Sack Baler Compactor is actively used across a wide range of industries, including construction and building materials, agriculture and farming, food and beverage processing, chemical and petrochemical, mining and minerals, plastics and rubber, cement and lime, waste management and recycling, pharmaceuticals, industrial manufacturing, and logistics and bulk packaging.

Integrate Your Bulk Bag Unloading System

Bulk Bag Unloader with Auxiliary Baler Compactor

Accomplish the Unloading and Disposing of Super Sacks with CMT's Bulk Bag Unloader-Compactor Combo. Our bulk bag unloaders boast the industry’s largest bag access chamber, or as we like to call it, the Contain-It™ Chamber. This large, User-Friendly Access Chamber t allows the operator to easily tie, retie, and handle FIBC Bulk Bags and Super Sacks in an enclosed, controlled, dust-tight chamber.

No more spilling excess material on your plant floor when shaking or handling the bag after discharge. We offer three main models (Hoist and Trolley Model, Short Frame Model, and Fork-Truck Loaded Model) with two types of bulk bag agitation: Paddle Agitation (Massage-It™) and Vertical Vibration (Shape-It™). Our bulk bag unloaders are the industry leading Dust Containment Units. After you have unloaded your bag, simply roll the plastics baler machine near the unloader, and insert any used bulk bags and watch your bags be compacted and plastic wrapped in a matter of minutes!

Technical Information

🔧 Technical Specifications & Features

- Designed for compacting super sacks and similar materials

- Equipped for 480 V (3 PH + N + PE) / 60 Hz electrical systems

- Three-phase gear motor: 3 kW, 480 V / 60 Hz, IP54 enclosure, IE3 efficiency class

- Heavy-duty base frame with robust main drive via roller chain

🧼 Maintenance & Accessibility

- Easy access for cleaning, maintenance, and service through side and rear inspection doors

- All inspection doors and flaps secured with safety switches for operator protection

🛡️ Safety & Control

- Safety panels installed at the feed table and bale ejection area

- Electrical control panel located at the front (feeding side) with main switch and reset button

- Control system includes reverse run capability and automatic overload protection

- Potentiometers allow adjustment of wrapping sequence and operation time

- Fully automated control of:

- Wrapping system

- Cutting of wrapping film

- Ejection door function

- Compacted bale ejection

-

🕹️ User Interface

- Control unit at the feed table includes:

- “Start”, “Stop”, and “Reverse Run” buttons

- Selector switches for:

- Operating mode

- Bale diameter settings

- Manual bale ejection door control

-

- Alarm signal for “Bale Full” condition

-

- Separate multifunction display provides:

- Continuous filling level status

- Daily and lifetime counters for:

- Operating hours

- Number of bales

-

-

🔔 Additional Features

- Flashing warning light to indicate “Bale Full”

- Bale counter at bale ejection section

- Mounted on castors for mobility

- 3-meter power connection cable included

- Machine finished in:

- RAL 7016 (framework)

- RAL 7038 (covers and doors)

-

♻️ Packaging & Dust Control

- Stretch wrap tying system, includes one roll of stretch wrap film

- Manual feed table for loading bulk bags or recyclables

- Dust hood above feed table with socket for central dust extraction system

- Dust collection drawer located beneath the machine

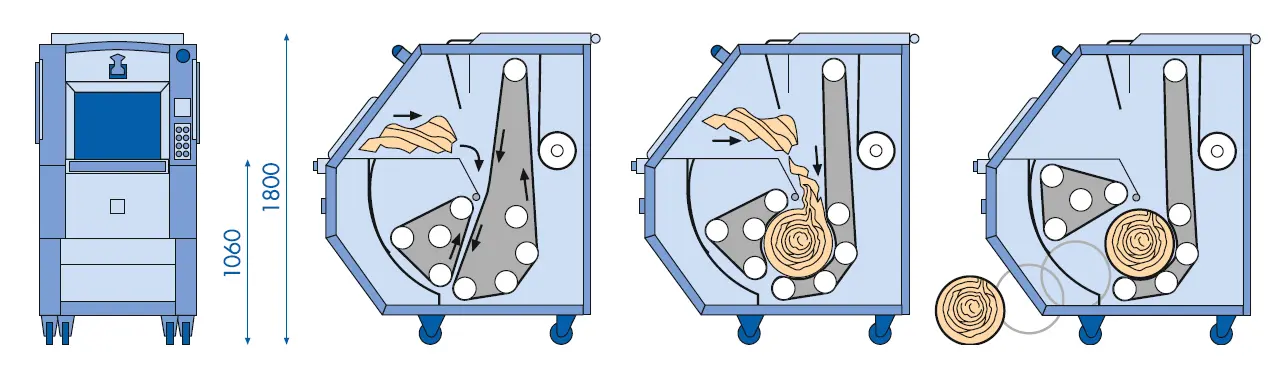

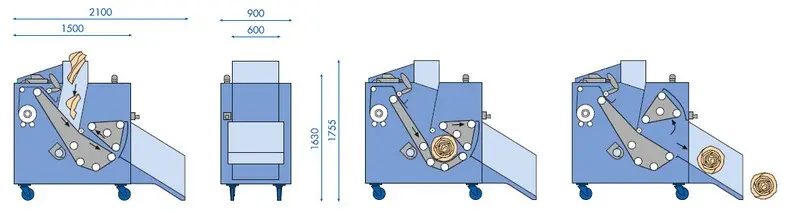

Description of working method:

After sorting the bulk bags or recyclable material, they are placed onto the machine’s feed table. The operator inserts the material into the chute, where it is automatically gripped by the conveyor belt and pulled into the compacting chamber. Inside the chamber, two rotating belts compress and roll the material, gradually forming a dense, cylindrical bale.

As additional material is fed into the chute, the machine continues compacting it into the growing bale. The process operates on-demand, allowing the operator to insert bulk bags or material continuously as needed. A built-in LED display provides real-time updates on the compaction progress.

Once the pre-set bale size is reached (the RC 655 offers three selectable bale diameters), the wrapping cycle begins. The operator inserts the stretch wrap film into the feed intake, and the machine automatically wraps the compacted bale. When wrapping is complete, the film is cut automatically.

To finish the process, the baling compartment opens with a simple push of a button on the operating console. The compacted bale is ejected, and the compartment closes automatically—fully automating both the wrapping and ejection stages.