Bolted Tanks

Bolted Tanks for Storage of Bulk Solids and Liquids

Bolted tanks and silos are vital to bulk material handling, providing secure, efficient, and customizable storage for a wide range of dry bulk products. They safely hold commodities like cement, fly ash, grain, sugar, lime, plastics, and frac sand—keeping them dry, contamination-free, and ready for use. Designed for seamless integration, they support flexible filling and unloading options, deliver consistent flow through smooth-wall designs, and can be engineered for mass or funnel flow depending on material needs.

Their versatility spans industries: in manufacturing they feed plastics and chemicals into production lines; in construction and mining they store cement and aggregates; in agriculture they hold grains and feed; and in energy and oilfield applications, API-certified silos withstand rugged conditions. With rapid installation, easy modular expansion, and the ability to relocate or repair by panel, bolted silos combine durability, flexibility, and cost efficiency, making them the backbone of modern bulk material handling systems.

Features and Advantages

Overview

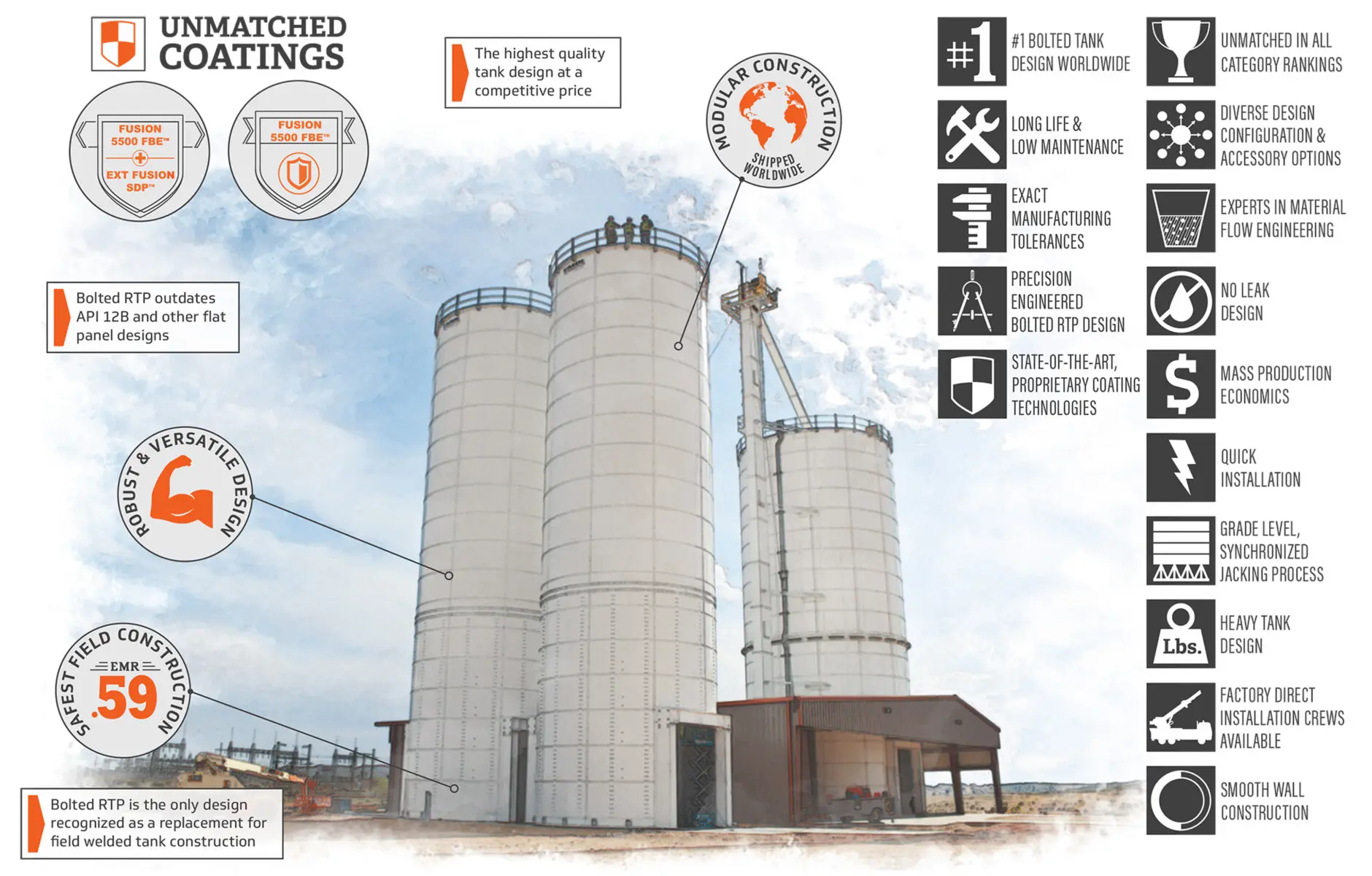

Bolted Tank Flanged Panel design and Flat Panel design each provide their own unique advantages. Both feature baked on coatings for long life and both designs are proven leak proof with thousands of installations worldwide. Based upon your needs we will recommend the correct design for your application.

Why Bolted Tanks?

Our bolted tanks are specially constructed to be leak proof, evident by the thousands used in liquid applications, as well as for bulk solids. They offer a cost effective alternative to welded silos and are recognized as an acceptable alternate to field-weld construction in the power industry (i.e., limestone, lime, water, fly ash, coal storage, etc.). Our Bolted Tanks incorporate heavy-duty, robust tank engineering designed for low maintenance and long term performance. The bolted RTP (rolled, tapered panel) tank construction outperforms all other types of bolted tank construction through its superior design, proprietary coating systems and safe field installation processes. Our team of experts have vast experience in tank design and process engineering, and will assist you in choosing the best design for your specific application.

Features

Applications: Water, wastewater, fire protection, cement, fly ash, coal, limestone, lime, aggregates, minerals, chemicals, plastics, select foods, wood waste & other miscellaneous dry products.

- Hopper capacities from 1000 – 100,000 cubic feet

- Liquid storage up to 8.2 million gallons

- Shop controlled quality

- Modular construction requires bolted field assembly

- Decreased field installation timeframe

- Factory applied powder coating systems

Email us at info@cmtnc.com or Fill Out the Contact Form Below