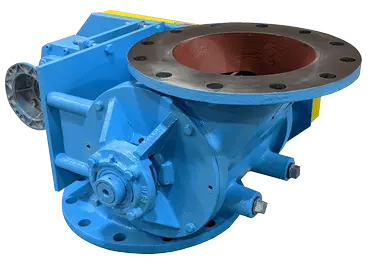

Diverter Valves

Diverter Valves to reroute powder, pellets or granules from one discharge to another

Carolina Material Technologies provides a full range of diverter valves. Diverter valves are used to divert product flow from one inlet to multiple outlets. These are applied to simple gravity applications (no pressure) and to high-pressure applications. To avoid plugging, leakage and premature wear it is always critical to divert when product is not flowing through the valve. Diverter Valves are ideal for handling dry bulk material in gravity flow, dilute phase or dense phase pneumatic conveying applications.

Quantum Wye Line™ Diverter Valve in Action

Email us at info@cmtnc.com or Fill Out the Contact Form Below