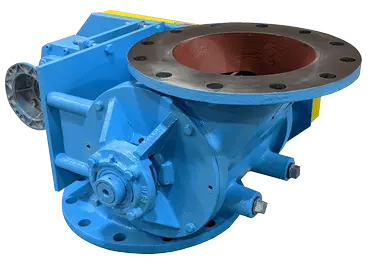

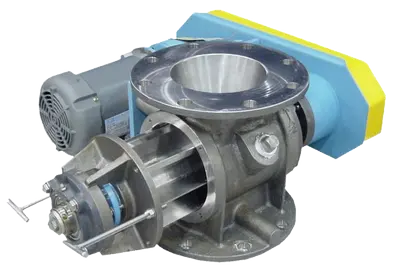

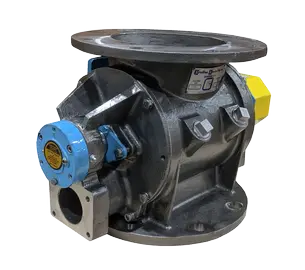

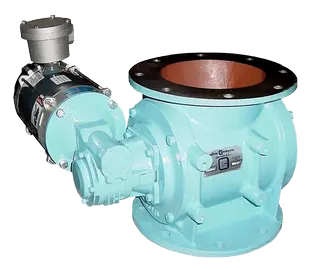

Rotary Valves

Rotary Valves for Pneumatic Conveying Applications

We provide a full range of heavy-duty valves including rotary airlock valves, diverter valves, weigh valves, slide gate valves, iris valves and maintenance gates. In addition, CMT provides butterfly, knife gates and orifice gates. Rotary Airlock Valves are used to introduce dry materials into a pressure conveying line “locking” the high-pressure (0-25 psig) air below the valve, thereby allowing material to be introduced into the conveying line.

A rotor, 6-12 vanes, delivers product on a continuous basis to the conveying line. The rotor shaft is supported by two externally located bearings, which is a potential point of product leakage. Rotary Airlock Valves typically run at very slow speeds – 5 to 26 rpm.

Many users have a “dislike” for rotary airlock valves, as they can be a source of high maintenance or unexpected breakdowns. Although high pressure, abrasive applications are difficult for any supplier, many problems experienced by users are a result of the wrong features being utilized for an application. Allow us to help solve your current problem by completely understanding your application and concerns.

Email us at info@cmtnc.com or Fill Out the Contact Form Below