Rubber Tubing Flex Sleeves

Rubber Tubing Flex Sleeves for Industrial Processes

Clear Poly Flex Tubing in Process Plant

We supply FDA-approved Flex Fittings and Flexible Rubber Sleeve Connectors engineered from a wide range of materials, including Clear Polyurethane, EPDM, Pure Gum Rubber, Rubber-Coated Nylon, Silicone, Neoprene, and more. Available in multiple configurations—such as straight sleeves, tapered sleeves, and bellowed flex fittings—our products are designed to provide reliable performance across demanding applications.

Our fittings are trusted in industries such as Food, Pharmaceutical, Beverage, Tobacco, Wood, Petroleum, Coal, Chemicals, Plastics, and Rubber.

During bulk material transfer—whether from trucks, railcars, silos, sifters, screeners, hoppers, screw feeders, vibratory feeders, bin dischargers, conveyors, or packing and filling equipment—it is critical that the materials used do not contaminate or alter the taste or quality of the product. For this reason, our flex fittings are manufactured with high-quality, tightly controlled compounds, ensuring compliance with stringent standards.

Many of our Flexible Rubber Sleeve Connectors are manufactured to meet FDA, NSF, USDA, and Sanitary 3A requirements, making them suitable for a broad range of sanitary and industrial applications. Our Flex Connectors are compatible with all types of material handling equipment, providing durability, flexibility, and peace of mind in operation.

þ Customize Frame Dimensions

þ Customize Agitation Type

þ Customize/Integrate Outlet Equipment

þ BFM Fittings

þ FDA Approved - Food, Pharmaceutical, Chemical

þ Anti-Static Options Available

Rubber Tubing Flex Sleeve Offerings

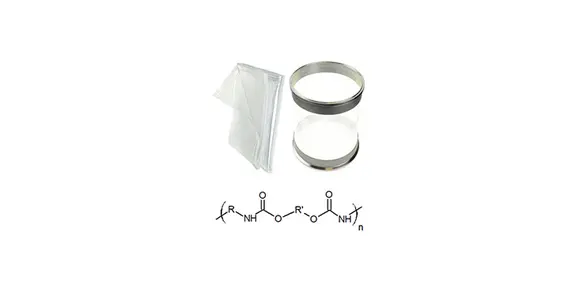

Polyurethane Flex Sleeves

Food-Grade Clear Poly Rubber Tubing provides product visibility and outstanding abrasion and chemical resistance.

Our Clear Polyurethane Flex Sleeves are available in both straight sleeve and tapered tubing designs, offering exceptional clarity for easy product viewing. Compared to other materials, Polyurethane provides superior abrasion resistance and excellent chemical durability, making it ideal for demanding applications.

In addition to standard extruded sizes, we also fabricate custom diameters and tapered boots to meet specialized requirements. Each sleeve is manufactured with our PerfectSplice technology, creating a seamless, virtually invisible splice without any compromise to material strength.

Tapered boots and tubing are available in 30 mil or 60 mil wall thicknesses, delivering the right balance of flexibility and durability for your process needs.

Poly Tubing Sleeving in Process Plant

Poly Tubing Bellowed Flex Fittings

Poly Tubing Flex Connectors

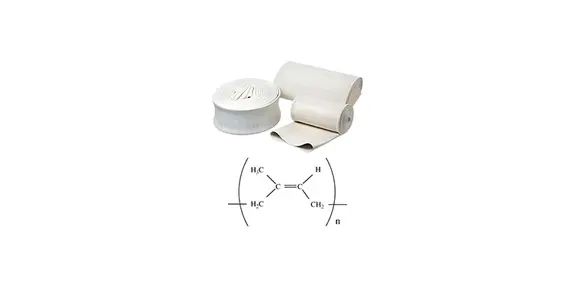

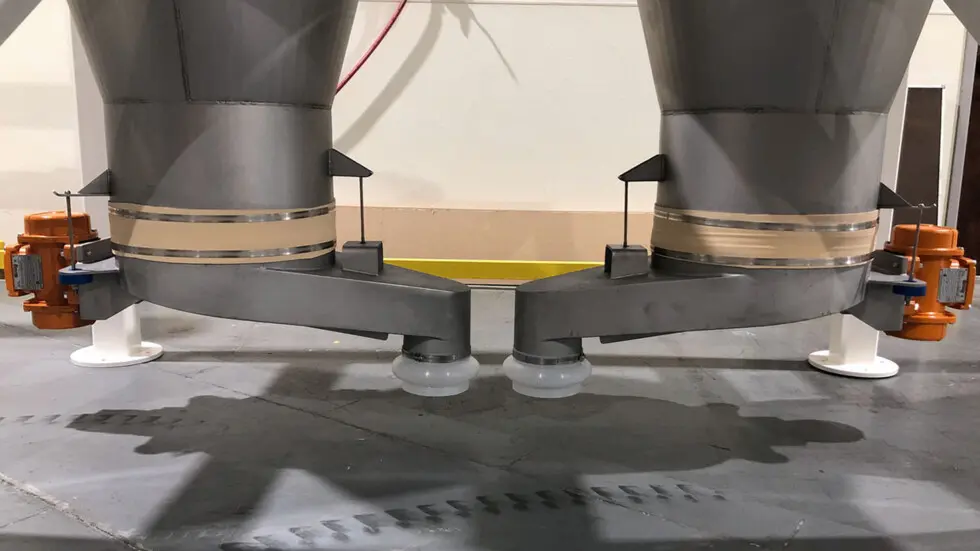

EDPM Rubber Tubing Flex Sleeves

Food-Grade EPDM Rubber Tubing Flex Sleeves Provide Superior Outdoor Weatherproof Benefits

Our Food-Grade EPDM Tubing Flex Connectors deliver outstanding durability and weather resistance, making them the ideal choice for outdoor process applications. Engineered from ethylene propylene diene monomer (EPDM), these connectors provide superior protection against oxygen, ozone, and sunlight exposure.

Designed to handle acids, oxygenated solvents, and abrasive materials, EPDM tubing is highly reliable in demanding transfer applications. With the ability to withstand temperatures up to 300°F, it is also resistant to polar materials such as phosphate esters, ketones, and alcohols. As a cost-effective alternative to silicone, EPDM offers long service life and excellent value, reducing maintenance costs and downtime. However, it should be noted that EPDM is not recommended for use with petroleum-based products.

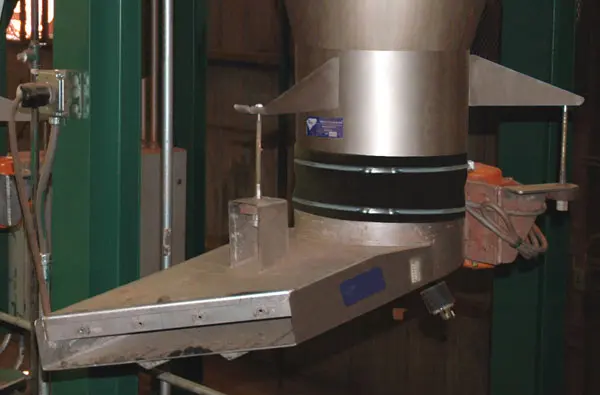

Black EPDM Flex Connector on Loss-in-Weight Feeders

Black EPDM Flex Connector on Loss-in-Weight Feeders

White Gum Rubber Flex Connector

Gum Rubber Tubing Flex Sleeves

Gum Rubber Sleeves Provide Excellent Abrasion Resistance, Flexibility, And Sealing Performance, Making Them Ideal For Bulk Material Transfer

Gum Rubber Tubing Flex Sleeves are a reliable, cost-effective solution for bulk material handling. Known for their excellent abrasion resistance and high flexibility, they provide long-lasting performance in high-volume transfer applications. Their tight sealing properties reduce leaks and product loss, while the non-marking surface ensures gentle handling of delicate products.

Available in FDA-compliant food-grade formulations, gum rubber flex sleeves are ideal for industries such as food, beverage, pharmaceuticals, plastics, wood, coal, and agriculture. Combining durability, versatility, and affordability, they deliver dependable performance across a wide range of demanding applications.

Gum Rubber Flex Connector on Loss-in-Weight Feeder

Gum Rubber Flex Connector on Pneumatic Conveying Line

Gum Rubber Flex Connector on Loss-in-Weight Feeder

Nitrile Rubber Tubing Flex Sleeves

Nitrile Rubber Tubing Flex Sleeves are highly durable and resistant to oils, fuels, and petroleum-based products.

Nitrile Rubber Sleeves are highly durable and resistant to oils, fuels, and petroleum-based products, making them ideal for demanding industrial environments. They offer excellent abrasion resistance, wide chemical compatibility, and strong mechanical performance across a broad temperature range. As a cost-effective alternative to specialty elastomers, nitrile sleeves deliver long-lasting reliability for chemical, petroleum, plastics, and general manufacturing applications.

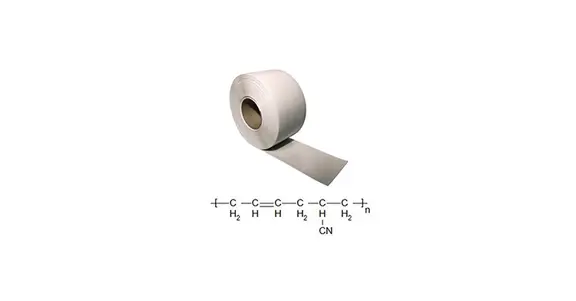

RCN Rubber Tubing Flex Sleeves

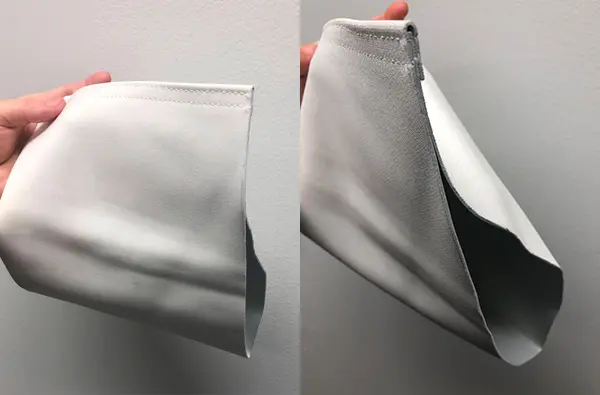

Rubber-Coated Nylon Sleeves Combine Lightweight Strength With Flexibility, Making Them Durable And Cost-Effective For Bulk Material Handling.

Rubber Coated Nylon Flex Fittings

Extremely Thin Fabric-Like Neoprene with Nylon Backing Suitable for Weighing Applications

Rubber-Coated Nylon Flex Sleeves combine lightweight strength with flexibility, ensuring durability and cost-effectiveness for bulk material handling applications. They resist tearing, punctures, moisture, and vibration while maintaining reliable performance indoors or outdoors. Versatile across food, plastics, chemical, and general manufacturing industries, these sleeves provide dependable connections and long-lasting value.

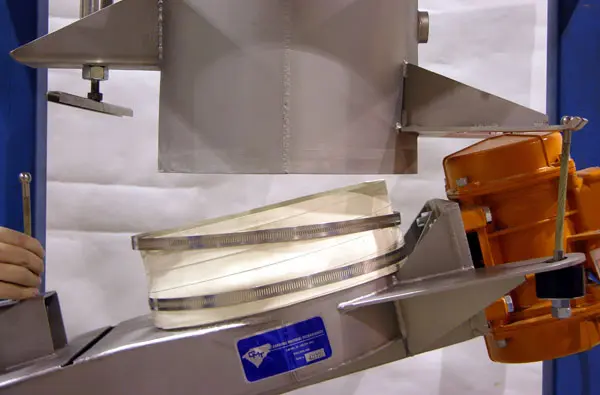

Silicone Tubing Flex Connectors

Silicone Flexible Connectors Provide Superior Flexibility, Precise Weighing Performance, And Long Service Life.

Silicone Weighing Bellows provide superior flexibility, precise weighing performance, and long service life. With excellent temperature resistance, food-grade compliance, and resistance to chemicals and weathering, they are ideal for sanitary bulk material handling in food, pharmaceutical, chemical, and fine powder applications.

Silicone Weighing Bellows are designed to connect loss-in-weight feeders and other load-cell-based equipment while ensuring precise and repeatable measurements. Their flexibility prevents stress transfer to load cells, while their food-grade compliance, chemical resistance, and wide temperature tolerance make them ideal for sanitary bulk material handling across food, pharmaceutical, chemical, and fine powder applications.

Silicone Weighing Flex Connector

Silicone Weighing Flex Connector

Silicone Weighing Flex Connector

Rubber Tubing Flex Sleeve Photo Gallery

Flex Fittings on Brick Coating Feeders

EPDM Flexible Rubber Sleeve Connectors on Brick Coating Feeders Connect Hopper to the Vibratory Feed Tray

Rubber Flex Fitting on Bin Activator

Gum Rubber Flexible Sleeve Connecting Bin Activator on Silo to Rotary Valve

Rubber Flex Fitting on Bin Activator

Pure Gum Rubber Sleeve Connecting a Bin Activator on Storage Tank

Flexible Rubber Sleeve on Slide Gate

Gum Rubber Sleeve Flex Connecting Tube from Slide Gate to Pneumatic Conveyor in Process Plant

Flex Fitting on Super Sack Unloader

Flexible Rubber Sleeve on Bulk Bag Unloader Connecting to a Pneumatic Conveying System

Flex Fitting on Vibratory Feeder

Flexible Rubber Sleeves on Batch Feeders with Silicone Bellows that will connect to Mixer

Email us at info@cmtnc.com or Fill Out the Contact Form Below