Super Sack Handling Equipment

Super Sack Handling Equipment for Bulk Bags

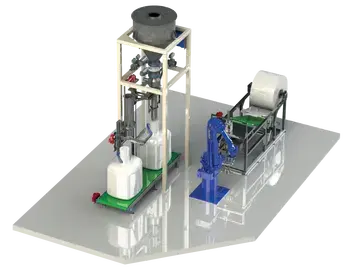

Complete Super Sack Handling Equipment Solutions for Emptying, Filling, and Disposing Bulk Bags

CMT Process Solutions is a leading provider of super sack handling equipment and one of the nation’s top systems integrators for bulk bags and FIBC super sacks. Whether you need to empty, discharge, fill, or dispense bulk bags, our team will design and deliver a bulk bag handling system that integrates seamlessly with your existing plant operations.

A safe and efficient super sack handling system is essential, as lifting super sacks that can weigh over 2,000 lbs creates significant labor challenges and safety risks. Our engineers have developed operator-friendly designs focused on safety, reliability, and dust-free operation.

Our comprehensive selection of super sack handling equipment includes bulk bag unloaders, bulk bag compactors, and super sack fillers — all built to improve productivity and minimize downtime.

þ Super Sack Unloaders & Fillers

þ Bulk Bag Compactors

þ Maximum Dust Control

þ Material Flow Optimizers

þ Engineered Turnkey-Systems

þ Customize to Fit Your Needs

Super Sack Handling Equipment

How Super Sack Handling Equipment Is Used in Bulk Material Handling

Super sack handling equipment (also known as bulk bag handling systems or FIBC equipment) is used to safely move, unload, and fill large bulk bags—often weighing up to 2,000 lbs—with powders, granules, or bulk solids. Because of their size and weight, handling super sacks manually is unsafe and inefficient. Specialized equipment solves this by:

- Supporting and Positioning Bags – lifting frames and bag supports hold the super sack securely in place.

- Controlled Discharge – unloaders regulate material flow from the bag spout into hoppers, conveyors, mixers, or feeders.

- Dust Control – clamp seals and extraction systems minimize dust release, keeping facilities cleaner and safer.

- Filling Operations – bulk bag fillers precisely load product into empty sacks by weight or volume for transport or storage.

- Compacting and Recycling – baler-compactors compress empty bags for cleaner disposal and space savings.

These systems are widely used in food, chemical, plastic, mineral, and pharmaceutical industries to improve safety, reduce labor costs, prevent spillage, and streamline production processes.