Flex Fittings & Rubber Sleeves

Flex Fittings and Flexible Rubber Sleeve Connectors

Food-Grade Flex Connectors for Connecting Adjoining Spouts on Hoppers, Mixers, Feeders, Silos, and More.

Clear Poly Flex fitting in Process Plant

We offer FDA-Approved Flex Fittings and Flexible Rubber Sleeve Connectors in several different materials, including Clear Polyurethane, EPDM, Pure Gum Rubber, Rubber Coated Nylon, Silicone, Neoprene, and more. We offer a variety of shapes, including straight rubber sleeves, tapered rubber sleeves, and bellowed flex fittings. Our flex fittings are used in a variety of industries, including Food, Pharmaceutical, Beverage, Tobacco, Wood, Petroleum, Coal, Chemicals, Plastics and Rubber.

Raw materials are often transferred between trucks, railcars, silos, sifters, screeners, hoppers, screw feeders, vibratory feeders, bin dischargers, conveyors, and packing and filling equipment. The materials used in these applications cannot contaminate or impact the taste or quality of the food or product being transferred. This requires flex fittings to use high quality, tightly controlled compounds during the manufacturing process. Many of our flexible rubber sleeve connectors will meet FDA, NSF, USDA, or Sanitary 3A standards. Our Flex Connectors are used on all types of material handling equipment, including

Connect Transitional Process Equipment

Polyurethane, EPDM, Gum Rubber

Nitrile, Neoprene, Silicone

BFM Fittings

FDA Approved - Food, Pharmaceutical, Chemical

Anti-Static Options Available

Available Flex Connectors

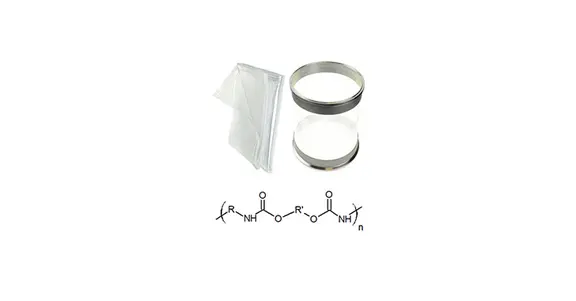

Polyurethane Flex Connectors

Polyurethane Flex Fittings

Clear Polyurethane Flex Connectors are available in straight sleeves, bellows, and BFM Fittings. Our Poly Flex Connector offers many advantages over other materials, including allowing for product viewing and offering superior abrasion and chemical resistance. In addition to the extruded sizes, non-standard diameters or tapered boots can be fabricated. They are built using the PerfectSplice. The splice is virtually invisible and no loss of material strength occurs in the process. The tapered boots / tubing can be made in 30 or 60 mil wall thickness.

Material Specs:

- MATERIAL: Poly Ether Urethane

- COLOR: Clear Transparent

- THICKNESS: 0.30", 0.60"

- TEMPERATURE RESISTANCE: Min: ‐104° F (‐40⁰C) Max: 194° F (90⁰C)

- HARDNESS: 85 Duro Shore A

Poly Flex Fitting Applications:

- Industrial and Process Equipment

- Screw Conveyors

- Volumetric Screw Feeders and Vibratory Feeders

- Connecting (2) Flange Outlets or Pipes

- Flexible Tubing

- Grommets

- Belts and Weigh Belt Feeders

- Hoppers

Sizes Available:

DIAMETERS

- 2" ID

- 3" ID

- 4" ID

- 5" ID

- 6" ID

- 7" ID

- 8" ID

- 9" ID

- 10" ID

- 12" ID

Advantages

- High Abrasion & Impact Resistance

- High Cut & Tear Resistance

- High Load Bearing Capacity

- Transparency for Product Viewing

- Resistance to Water, Oil & Grease

- Ozone Resistance

- Electrical Insulating Properties

- Performance in Harsh Environments

- Mold, Mildew & Fungus Resistance

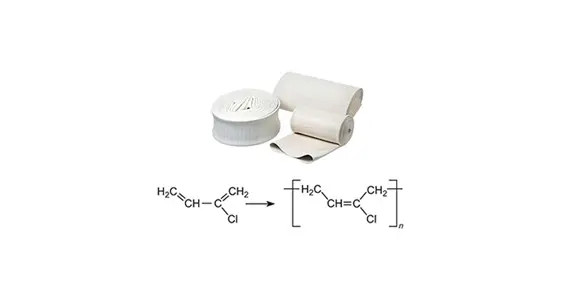

EPDM Flex Connectors

EPDM Flex Fittings

Food-Grade EPDM Tubing Flex Connectors Provide Superior Outdoor Weatherproof Benefits

EPDM (ethylene propylene diene monomer) tubing is exceptional for connecting two pieces of equipment in outdoor process applications. EPDM is a terpolymer of ethylene, propylene and a diene monomer, making these flex connectors resistant to oxygen, ozone, and sunlight. Our EPDM tubing flex flex fittings are excellent at handling acids, oxygenated solvents and wet or dry abrasive materials. This material is frequently used in process applications requiring outdoor exposure, as EPDM can withstand temperatures up to 300°F. It is resistant to polar materials such as phosphate esters, many ketones and alcohol. This type of rubber is a cost-effective alternative to silicone, as it can last for long periods of time with proper use. As a result, EPDM can save you time and money depending on the needs of your application. However, it must be noted that its resistance to petroleum products is poor.

Material Specs:

- MATERIAL: Ethylene-Propylene-Diene Rubber

- COLOR: Black or White

- THICKNESS: Stock : 1/8", 3/16" Special Order: 1/4", 3/8"

- TEMPERATURE RESISTANCE: Min: -60° F (‐51⁰C) Max: 350° F (177⁰C)

- Hardness: 60 Duro Shore A

EPDM Flex Fitting Applications:

- Industrial and Process Equipment

- Screw Conveyors

- Screw Feeders and Vibratory Feeders

- Connecting (2) Flange Outlets or Pipes

- Tubing

- Belts and Weigh Belt Feeders

- Hoppers

- Grommets

- Water system O-rings and hoses

Sizes Available:

DIAMETERS

- 2" ID

- 3" ID

- 4" ID

- 5" ID

- 6" ID

- 7" ID

- 8" ID

- 9" ID

- 10" ID

- 12" ID

- 13" ID

- 14" ID

- 15" ID

- 16" ID

- 18" ID

- 20" ID

- 21" ID

- 22" ID

- 23" ID

- 24" ID

Advantages

- Resistance to UV exposure, ozone, aging, weathering, and many chemicals – great for outdoor applications

- Stability in high and low temperatures – a general purpose EPDM material can be used in an environment where the temperature range is from -20⁰F to +300⁰F (-29⁰C to 149⁰C).

- Low electrical conductivity

- Steam and water resistant

- Can be fabricated in a variety of ways, which includes custom molded and extruded parts

- Long-term part lifespan allows for fewer replacement parts, saving money in the long run

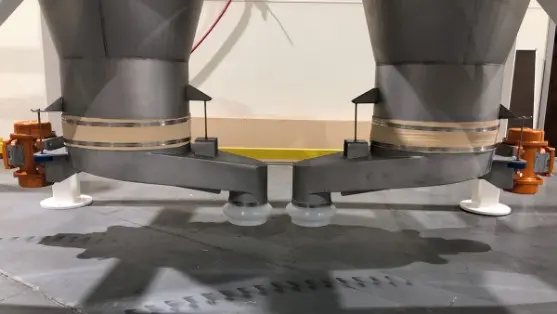

Black EPDM Flex Connector on Loss-in-Weight Feeders

White Gum Rubber Flex Connector

Black EPDM Flex Connector on Loss-in-Weight Feeders

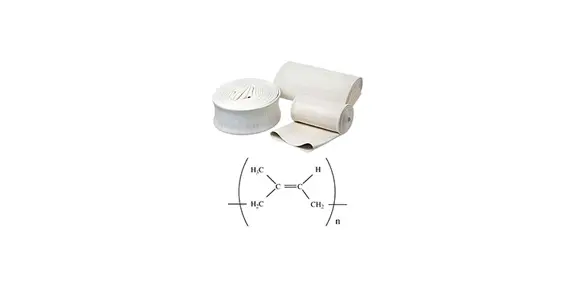

Gum Rubber Flex Connectors

Gum Rubber Flex Fittings

Cost-Effective General Purpose Sleeve With High Tensile-Strength

Gum Rubber Flex Fittings are specially made for weather and ozone resistance. Gum Rubber has excellent tensile, elongation, tear resistance and resilience. It has good abrasion resistance and excellent low temperature flexibility. Gum Rubber Flex Connectors have certain limitations, such as poor resistance to solvents and petroleum products. However, the all-purpose quality of Gum Rubber makes it a best seller for in the materials processing industry, and is the most commonly used tubing in practically every industry.

Material Specs:

- MATERIAL: Natural Gum Rubber Polyisoprene

- COLOR: White or Tan

- THICKNESS: Stock : 1/8", 3/16", 1/4" Special Order: 1/16", 3/8"

- TEMPERATURE RESISTANCE: Min: -78° F (‐60⁰C) Max: 220° F (105⁰C)

- Hardness: 40 Duro Shore A

Gum Rubber Flex Fitting Applications:

- Industrial and Process Equipment

- Screw Conveyors

- Screw Feeders and Vibratory Feeders

- Connecting (2) Flange Outlets or Pipes

- Tubing

- Belts and Weigh Belt Feeders

- Hoppers

Sizes Available:

DIAMETERS

- 2" ID

- 3" ID

- 4" ID

- 5" ID

- 6" ID

- 7" ID

- 8" ID

- 9" ID

- 10" ID

- 12" ID

- 13" ID

- 14" ID

- 15" ID

- 16" ID

- 18" ID

- 20" ID

- 21" ID

- 22" ID

- 23" ID

- 24" ID

Advantages

- Can be compounded to meet nearly any mechanical requirement

- Ability to be electrically insulating or fully conductive

- Protection, insulation, and sealing properties

- Absorb vibration and silence noise

- Very elastic without permanent deformation

- Great for machinery with large movement or displacement

- Low temperature flexibility

- Good resistance to ozone

Gum Rubber Flex Connector on Pneumatic Conveying Line

Gum Rubber Flex Connector on Loss-in-Weight Feeder

Gum Rubber Flex Connector on Loss-in-Weight Feeder

Nitrile Rubber Flex Connectors

Nitrile Flex Fittings

Superior strength and high resistance to oils, fuels, and other chemicals

Buna-N Rubber, also called nitrile-butadiene rubber (NBR, Nitrile), is a synthetic rubber that provides excellent resistance to petroleum-based oils as well as mineral and vegetable oil. Our Buna-N Rubber Nitrile Tubing Flex Fittings can withstand a range of conditions in order to suit your specific application. Nitrile / BUNA-N is a copolymer of acrylonitrile and butadiene. It has excellent physical properties, however its claim to fame is based on its resistance to water, petroleum products and fuels. In the white formulation it is 3A rated. Useful temperature range is -40⪚ F to +220° F.

Our Buna-N Rubber Nitrile Flex Connectors display excellent resistance to petroleum-based oils, fuels, water, alcohols, silicone greases, and hydraulic fluids. The chemical and oil resistance, along with a good balance of desirable working properties like low compression set, high abrasion resistance and high tensile strength, makes Nitrile a favorite among chemical and process engineers. Our Buna-N Flex Connectors are also a great choice for applications that require abrasion resistance and metal adhesion. The drawbacks of Buna-N Nitrile include poor ozone and sunlight resistance, below average weather resistance, and poor flame resistance.

Material Specs:

- MATERIAL: Butadiene Acrylonitrile

- COLOR: White or Tan

- THICKNESS: Stock : 1/8", 3/16", 1/4" Special Order: 1/16", 3/8"

- TEMPERATURE RESISTANCE: Min: ‐30° F (‐34⁰C) Max: 250° F (121⁰C)

- Hardness: 60 Duro Shore A

Nitrile Flex Fitting Applications:

- Industrial and Process Equipment

- Bin Activators and Silos

- Oil Related Applications

- Screw Conveyors

- Screw Feeders and Vibratory Feeders

- Connecting (2) Flange Outlets or Pipes

- Oil Related Tubing

- Weigh Belt Feeders

- Hoppers

Sizes Available:

DIAMETERS

- 2" ID

- 3" ID

- 4" ID

- 5" ID

- 6" ID

- 7" ID

- 8" ID

- 9" ID

- 10" ID

- 12" ID

- 13" ID

- 14" ID

- 15" ID

- 16" ID

- 18" ID

- 20" ID

- 21" ID

- 22" ID

- 23" ID

- 24" ID

Advantages

- Resistance to Oil and Petroleum Products

- Excellent for Sealing Applications

- Abrasion Resistance

- Heat Resistance

- Abrasion Resistance

- Water and Moisture Resistance

- Resistance to Gas Permeability

- Great for Applications involving temperatures up to 250°F

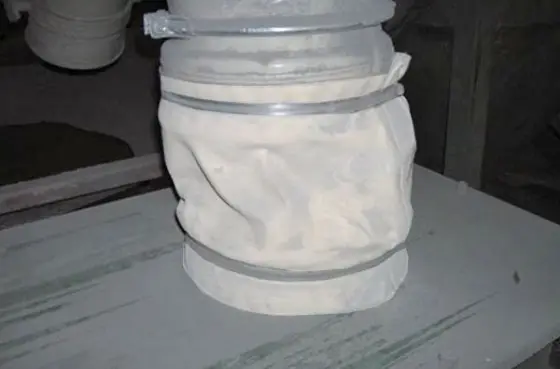

RCN Flex Connectors

Rubber Coated Nylon Flex Fittings

Extremely Thin Fabric-Like Neoprene with Nylon Backing Suitable for Weighing Applications

Rubber Coated Nylon flex sleeves are an industry standard, but RCN is only one of many fabrics available to you. These light-weight sleeves are made with Neoprene and have a Nylon backing. Rubber Coated Nylon sleeves are very pliable, soft rubber coated on a two-way stretch nylon backing. RCN Sleeves feature sewn inside hems, shock cord is a very reliable elastic cord. Installed at 75% of the specified sleeve diameter, shock cord can be used to secure non-stressed sleeves to spout openings without the need for clamps or other fasteners.Popular uses include vibratory feeders, screw feeders, and other applications that involve load-cells where minimal impact is a must.

Material Specs:

- MATERIAL: Neoprene (Polychloroprene) and Nylon 66

- COLOR: White

- THICKNESS: Stock : 1/16"

- TEMPERATURE RESISTANCE: Min: ‐50° F (‐45⁰C) Max: 200° F (93⁰C)

- Hardness: 30 Duro Shore A

Nitrile Flex Fitting Applications:

- Industrial and Process Equipment

- Weighing Applications

- Screw Feeders and Vibratory Feeders with Load Cells

- Connecting (2) Flange Outlets or Pipes

- Belts and Weigh Belt Feeders

- Hoppers on Load Cells

Sizes Available:

DIAMETERS

- 2" ID

- 3" ID

- 4" ID

- 5" ID

- 6" ID

- 7" ID

- 8" ID

- 9" ID

- 10" ID

- 12" ID

- 13" ID

- 14" ID

- 15" ID

- 16" ID

- 18" ID

- 20" ID

- 21" ID

- 22" ID

- 23" ID

- 24" ID

Advantages

- Resistance to Solvents

- Excellent for Weighing Applications

- Interior Glossy Nylon Coating

- Water and Weather Resistance

- Resistance to Gas Permeability

- Minimal Impact on Load Cells

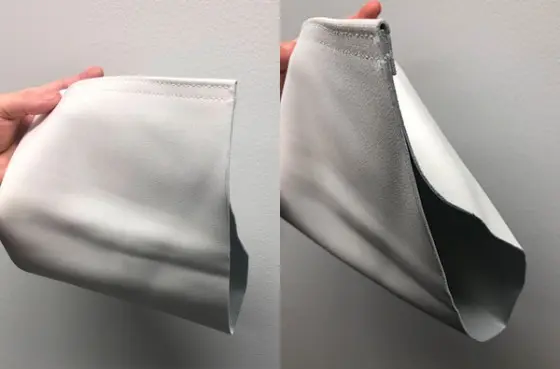

Silicone Flex Connectors

Silicone Flex Fittings

Soft Flexible Silicone Rubber Tubing for Process Weighing Applications

Silicone rubber contains many highly desirable qualities for manufacturing processes, including its flexibility, biocompatibility, and resistance to temperatures, UV light, radiation, and ozone. Silicone's unique properties make it particularly useful in the chemical, pharmaceutical, aerospace, and biomedical industries. Silicone rubber is one of the most commonly used synthetic rubbers on the market. It is composed of silicone bonded with hydrogen, carbon, and oxygen to create cross-linked polymers reinforced with silica, creating a unique synthetic elastomer that offers mechanical and chemical characteristics for the most rigorous applications.

Material Specs:

- MATERIAL: Silicone (polysiloxanes)

- COLOR: Translucent White

- THICKNESS: Stock : 2mm

- Hardness: 60 Duro Shore A

- TEMPERATURE RESISTANCE: Min: ‐76° F (‐60⁰C) Max: 392° F (200⁰C)

Nitrile Flex Fitting Applications:

- Industrial and Process Equipment

- Weighing Applications

- Screw Feeders and Vibratory Feeders with Load Cells

- Sound and Vibration Dampening Equipment

- Belts and Weigh Belt Feeders

- Hoppers on Load Cells

Sizes Available:

DIAMETERS

- 2" ID

- 2.5"

- 3"

- 4"

- 4.5"

- 5"

- 6"

- 6.5"

- 8"

- 10"

- 12"

- 14"

Advantages

- High Temperature Resistance Compared to Other Common Rubbers

- Excellent Thermal Stability

- Can withstand long-term, continuous use even at 200°C (392°F)

- Repels Water and Forms Tight Seals

- Excellent Electrical insulation

- Carbon Black Additives Increase Electrical Conductivity

- Flexible at Low Temperatures, Stiffens up at Higher temperatures

- Contact with Steam Causes Little or No Deterioration

- Red Silicone Flame Retardant (Only Available in Straight Sleeve)

- Low Chemical ReactivityTemperature Resistance: -76 °F to 392 °F (-60 °C to 200°C)

- Maximum Surge Temperature: 428 °F (220 °C)

- Elongation to failure: 240%

- Color: Translucent White

Silicone Weighing Flex Connector

Silicone Weighing Flex Connector

Silicone Weighing Flex Connector

Flex Fitting Showcase

Ensure Dust-Tight Connections with Flexible Rubber Sleeves

Rubber Flex Fitting on Bin Activator

Gum Rubber Flexible Sleeve Connecting Bin Activator on Silo to Rotary Valve

Rubber Flex Fitting on Bin Activator

Pure Gum Rubber Sleeve Connecting a Bin Activator on Storage Tank

Flex Fittings on Brick Coating Feeders

EPDM Flexible Rubber Sleeve Connectors on Brick Coating Feeders Connect Hopper to the Vibratory Feed Tray

Flex Fitting on Super Sack Unloader

Flexible Rubber Sleeve on Bulk Bag Unloader Connecting to a Pneumatic Conveying System

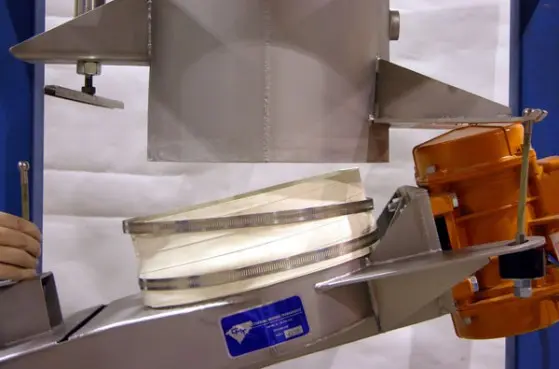

Flex Fitting on Vibratory Feeder

Flexible Rubber Sleeves on Batch Feeders with Silicone Bellows that will connect to Mixer

Flexible Rubber Sleeve on Slide Gate

Gum Rubber Sleeve Flex Connecting Tube from Slide Gate to Pneumatic Conveyor in Process Plant

Email us at info@cmtnc.com or Fill Out the Contact Form Below