Bulk Bag Filling Systems

bulk bag fillers for Efficient Dust-Free Super Sack Filling

Manual and Automatic Super Sack Filling Systems for Powders, Granules, and Solids

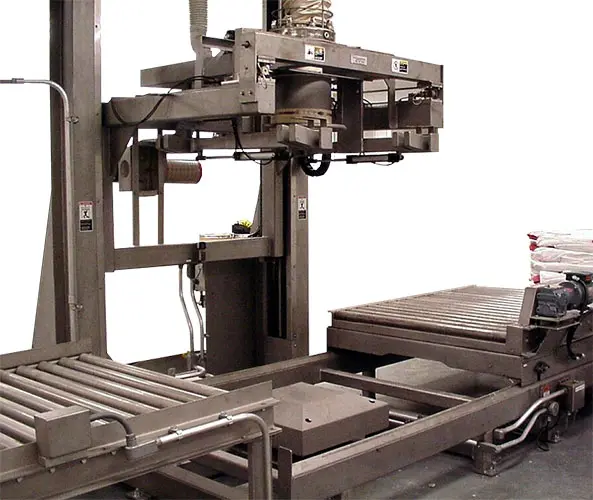

CMT provides Bulk Bag Filling System Solutions, ranging from Semi-Automatic to Fully Automated Robotic Solutions. Our Super Sack Filling encompasses low, medium, and heavy volume operations for a wide-range of industries, including the Food, Plastics, Chemicals, Pharmaceuticals, Nutraceuticals, Biomass, and Mineral Industries. Our newest fully-automatic systems were engineered with integrated palletizing and shrink wrapping. Contact one of our material handling experts to assist you in the selection process, in order to fit your budget and application requirements. Our systems strive on delivering optimum performance across flow capacity ranges with maximum cost-effectiveness.

þ Manual Stand-Alone Units Available

þ Volumetric or Weight-Based Filling

þ Dust Extraction Systems Available

þ Fully Automatic Systems Available

þ Vibration Technologies for Product Densification

þ Easily Integrated With Other Equipment

Equipment Available

Types of Bulk Bag Filling Systems

Bulk Bag Filling Station

Bulk Bag Filling Stations easily support and fill bulk bags, super sacks and FIBCs with dry products. Different styles are available from the very simple fill heads with a support framework to more complex units with bag inflators, vibration to de-aerate the product and load cells for weighing and batch control.

The standard Bulk Bag Filling Station consists of an adjustable height framework, bag support arms, filling head with an inflatable seal, support platform and vibrator motor. The bag lifting loops are hung off the bag support arms to help the bag keep its shape during filling. The support arms are adjustable both horizontally and vertically for varying size bags. Vibration makes sure that the product de-aerates and maximizes bag volume. The filling head consists of an inner and outer feed tube with a dust extraction spigot and inflatable seal. The bulk bag inlet spout is inserted over the feed tube outlet, and the seal is inflated to create a dust-tight connection between the fill head and bulk bag. Learn More

þ Adjustable Support Frame for Various Bulk Bag Heights

þ Adjustable Bag Lifting Loops for Various Bag Spout Lengths

þ Fill Head with Inflatable Seal for Dust Control

þ Portable Units movable by Fork Lift Truck

þ Integral Weighing Options for Controlled Filling

þ Integral Vibration Options for Bag Densification

þ Simple and Economical Design

þ Customizable with Existing Equipment

Email us at info@cmtnc.com or Fill Out the Contact Form Below