Baler Compactor Machine

Streamline industrial recycling with our heavy-duty baler compactor.

Our commercial baler is ideal for compressing and compacting packaging waste to boost efficiency and savings in Labor, Storage, and Transportation

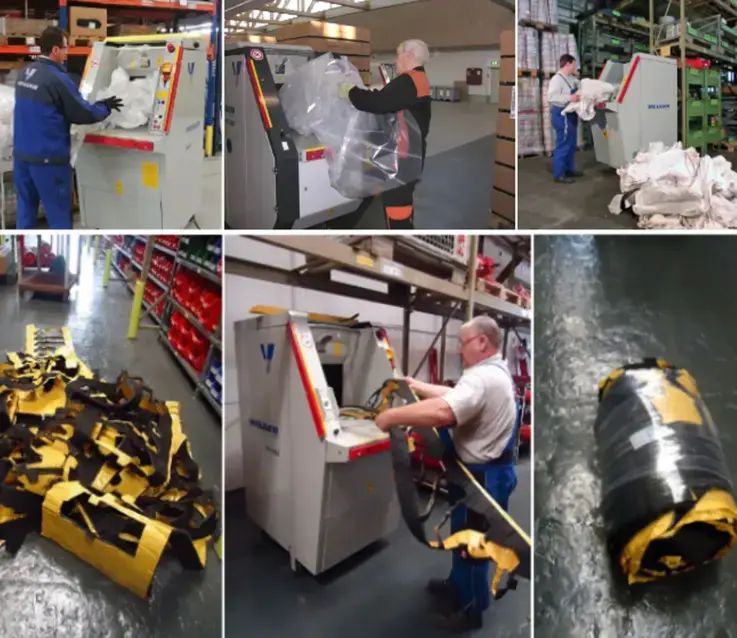

CMT offers a versatile Multi-Purpose Baler Compactor designed to simplify commercial and industrial waste disposal and recycling. Its compact, mobile design allows seamless integration into key areas of your facility where recyclable materials are generated. This powerful Industrial Recycling Baler Compactor efficiently handles a wide range of materials, including films, cardboard packaging, plastic foam, paper, fleece materials, and more. By significantly reducing the volume of waste, it helps cut costs related to labor, storage, transportation, and disposal. At the same time, it enhances on-site hygiene and minimizes the risk of employee injury and health hazards.

þ FIBC Super Sacks

þ Plastic Films and Foils

þ Scrap Tape and Fleece Materials

þ Sponge or Foam Packaging Materials

þ Corrugated Cardboard Packaging

þ Compact and Mobile Design

Features and Advantages

The baler compactor machine offers a practical solution for reclaiming valuable warehouse compacting packaging waste and industrial recycling materials. It automatically compresses and rolls materials into tightly packed bales, streamlining waste management. Designed to be mobile and compact, it fits easily into existing plant layouts without occupying excessive space. In addition to enhancing hygiene and sanitation conditions within factories and warehouses, the unit is equipped with advanced safety features to protect operators during use. Its heavy-duty construction ensures reliable performance without sacrificing space efficiency, while also delivering significant cost savings on labor, storage, and transportation.

Benefits of the Baler Compactor

- Compact, Space-Saving Design – Easily fits into tight industrial or commercial spaces.

- Mobile and Versatile – Lightweight and easy to move for flexible integration in any workflow.

- Heavy-Duty Durability – Built to withstand continuous daily use in demanding environments.

- User-Friendly Operation – Designed for high operator comfort and ease of use.

- Automatic Wrapping System – Streamlines the baling process and boosts efficiency.

- Enhanced Workplace Hygiene – Helps maintain cleaner, safer working conditions.

- Advanced Safety Features – Reduces the risk of employee injury and health hazards.

- Significant Cost Savings – Cuts labor, storage, transportation, and disposal costs.

Technical Advantages

- Heavy duty base frame and strong main drive via roller chain

- Two counter rotating belts

- Easy accessibility for cleaning & maintenance via inspection doors

- Mechanical Safety Switches – Front, both sides, each door

- Stretch Wrap, for wrapping product. Replaceable rolls. One roll included

- Feed table for manual loading of baling material with three sided safety switches

- Compacts 4-6 bulk bags, depending upon size, into one wrapped roll.

- Max Bale Size: 16” dia. x 24” long

- Throughput: 1.2 ft/second. Up to 660 lbs./hour

- Machine Specifications: 64”x 37”x 74” tall. 1485 lbs

- Gearmotor: 4HP, 480/60/3, IP 54, effiency class IE3

- Mild Steel Construcion with RAL 7016 (framework) and RAL 7038 (covers & doors)

Compactable Materials

The industrial recycling baler compactor machine is a roll-compactor-style baler built to process a wide variety of flexible recyclable materials with high compression efficiency. The machine can handle some of the most popular packaging materials in manufacturing, including:

- Super Sacks and Big Bags (e.g., Bulk Bags and FIBC)

- Plastic Films and Foils (including stretch wrap, shrink film, blister film, packaging film, and plastic bags)

- Scrap Tape and Fleece Materials

- Sponge or Foam Packaging Materials (such as soft sponges or cushioning foam)

- Corrugated Cardboard Packaging, Folding Cartons (Paperboard Boxes), Cardboard Sleeve Packaging, Cardboard Tubes & Cylinders

Technical Information

- For compacting super sacks and similar material, equipped with electrical equipment suitable for operating voltage 480 V (3 PH + N + PE) / 60 Hz

- Three-phase gear motor 3 kW, 480 V / 60 Hz, enclosure IP 54, efficiency class IE3, Heavy duty base frame and strong main drive via roller chain

- Easy accessibility for cleaning, maintenance or service via the inspection doors on the machine’s side walls and on the rear wall

- Inspection doors and flaps are secured by safety switches

- Safety panels at the feed table and at the bale ejection

- Electrical control panel with main switch and reset button at the front (feeding side)

- Electrical control prepared for reverse run with automatic overload protection with potentiometers to adjust wrapping sequence and to adjust operating time

- Fully automatic control for wrapping system, cutting of wrapping film, function of ejection door and compacted bale ejection,

- Control unit at the feed table featuring “start”, “stop” and “reverse run” buttons with selector switches for setting mode of operation and for setting different bale diameters, with switch to operate bale ejection door manually and with an alarm to signal "bale full"

- Separate multi-function display for continuous indication of filling level and with daily and lifetime counters for operating hours and number of bales

- Additional flashing light to indicate “bale full”

- Bale counter at the compacted bale ejection

- Castors on the stands

- 3-meter connection cable to power supply

- Machine finish according to RAL 7016 (framework) and according to RAL 7038 (covers & doors)

- Stretch wrap tying including 1 roll of stretch wrap plastic film, fitted to the machine

- Feed table for manual loading of recycling material

- Dust hood above feed table with socket pipe for connection to central dust extraction

- Dust collection drawer below the machine

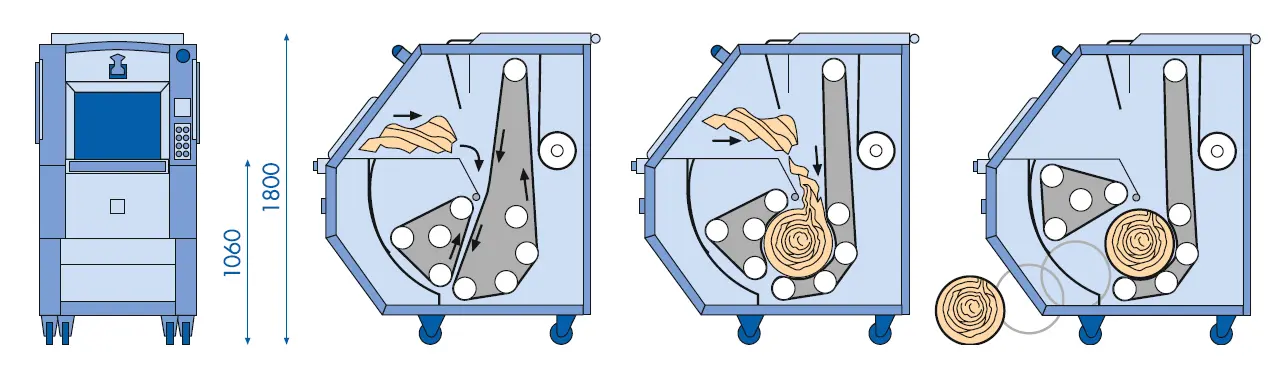

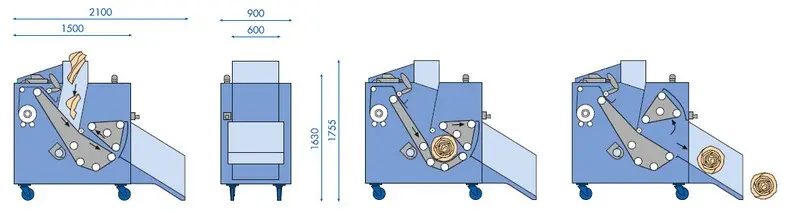

Description of Working Method

After sorting out the packaging waste or recycling material, it can be placed on the table of the machine. Insert the material into the chute, allowing the conveying belt to grasp it and pull it into the compacting chamber and where it is then rolled by the machines rotating action of two belts. As more and more packaging waste material is inserted into the chute, the two conveying belts form a cylindrical bale where the recyclable material or waste is compacted. The material remains compacted inside the machine, allowing the compacting process to take place on-demand and allowing the operator to insert packaging waste as needed. The compacting progress is displayed continuously via an LED display. After achieving the pre-selected bale size (Model RC 655 has three bale diameters that can be selected), the bale wrapping is initiated by pulling the plastic wrap and inserting it into the feed intake chute. The compacted material is then automatically wrapped with the plastic film. After the wrapping process is completed, the plastic film is automatically cut by the machine. The baling compartment is then opened with a push of a button on the operating console and will close again automatically after having ejected the compacted bale. The RC 655 fully automates the cutting process, as well as ejecting the compacted recyclables.