IMI Industrial Magnets

IMI Magnets for Ferrous Metal Separation and Extraction in Process Lines

Ensure Your Product Quality and Purity by Extracting Unwanted Metal During the Manufacturing Process

Carolina Material Technologies supplies a wide range of Heavy Duty Magnets and Magnetic Separators for the Removal of Ferrous and Non-Ferrous Metal Contaminants from Dry or Liquid Production Lines and Processes. Our magnetic separators utilize 50 MgOe rated rare earth magnets, which are approximately 20 times stronger than old, ceramic magnets. We specialize in custom configurations for industrial applications. Our magnetic separators are used in industries such as food, chemical, plastics, and feed and grain, to improve product purity and quality, and extend the life of your process equipment by protecting it from unnecessary damage.

þ 13,000 Gauss Rating

þ 52 MgOe Rare Earth Material

þ Dry or Liquid Product Flows

þ Remove Unwanted Metal to Purify Products

þ Protect Equipment from Damage

þ Industrial Strength Magnetic Separation

Magnet Selection

Available Products

We offer Five Main Categories of Magnets for the Removal of Tramp Metal during Industrial and Manufacturing Processes:

- In -Stream Gravity Feed Magnetic Separators - Magnets Inside The Product Stream that Directly Contact the Product, for the Extraction of Large and Fine Metal Particles in Conveyed or Gravity Flow Applications

- Out-Stream Gravity Feed Magnetic Separators - Magnets Outside The Product Stream that Do Not Directly Contact the Product, but Close Enough to Extract Larger Metal Particles Such as Nuts and Bolts in Conveyed or Gravity Flow Applications

- Conveyor Line Magnetic Separators - Permanent and Electro Magnets for Over and Under the Belt in Conveyor Line Applications

- Pneumatic Line Magnetic Separators - Magnets for the Extraction of Tramp Metal in the Product Line for Pneumatic Line Applications

- Liquid Line Magnetic Separators - Magnets for the Extraction of Tramp Metal in the Product Line for Liquid Line Applications

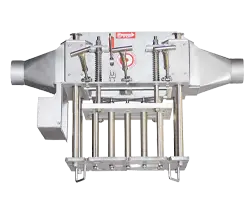

FEATURED PRODUCT

IMI’s MTH™ (Mid Tube Housing) incorporates 2 inch diameter Rare Earth tubes on 4 inch centers into our proven Drawer-In-Housing configuration for optimum ferrous metal separation for difficult flowing products. The spacing between the tubes is much larger than in a traditional housing with 1 inch diameter tubes, allowing for product to flow freely through the housing. The 52MgOe magnetic circuit achieves 28 lbs. of pull value on a 1/2” ball - the highest value of any circuit available on the market. Combined with a gauss averaging 13,000, our design offers the strongest and most effective solution to capture ferrous pieces, as well as smaller fines and weakly magnetic contaminants from a product flow.

FEATURES:

- Powerful 52 MgOe Rare Earth Circuit - Designed for optimum reach-out and surface holding strength

- 13,000 Gauss Rating

- BUNA Wiper Seals - for removing collected metal

- Compression Spring Assisted Seal Plate

- Stainless Steel Construction

- Food Grade Silicone Gasket Material - for leak resistant operation

- Drawer and/or Guard Lock-Out

- Hinged Rear Access Door with Lock-Out

- Collection Pan for Captured Metal

- Tool Free Guard Removal

- Pneumatic cylinders for actuating self-cleaning

- Self Clean models’ cylinders include magnetic pistons for optional Reed switching

Gravity Magnets (In-Stream)

GRAVITY FEED APPLICATIONS

MAGNETS INSIDE OF THE PRODUCT STREAM

Large Tube Housing® Magnets

- Designed for applications that have a tendency to bridge or plug a standard Drawer-In-Housing.

- Large 3" diameter tubes allow enough room for high volume product flows while capturing ferrous metal

- Ideal for flour, powdered sugar or moist products

- Powerful 52 MgOe Rare Earth Circuit

- BUNA Wiper Seals -for removing collected metal

- Compression Spring Assisted Seal Plate

- Stainless Steel Construction

- Food Grade EPDM Gasket Material - for leak resistant operation

Drawer-In-Housing Magnets

- Designed for ferrous metal separation in dry processing systems

- Separation is achieved with magnetic tubes assembled in a drawer

- Tubes are aligned on alternating centers for multiple row drawer configurations forcing the product flow in a zig-zag pattern while contacting the magnetic tubes

- The cascade effect ensures maximum tramp metal separation by causing product to have repeated and intimate contact with the magnetic tubes

- Clean the tubes regularly to prevent build-up and wash-off of collected metal

- NEW -- 2" MTH™ (Mid Tube Housing)

Magnetic Tubes

- Individual magnetic grate tubes

- Available in either round or square styles

- Designed for Customers looking to fabricate their own systems for special applications requiring non-standard spacing or tube arrangement

- Constructed from stainless steel and are standard in our Customary Grade finish

- Food Grade & Sanitary Grade finishes also available.

- Availalbe in Ceramic For small to large ferrous particle separation (nails, bolts, washers, etc.)

- Availalbe in Rare Earth UHI-52™ used for "fine particle" separation such as metal filings, shavings, metal wear residue, work hardened stainless steel, etc.

Magnetic Grates

- Delivers ferrous tramp metal separation in bins, chutes, drawers, hoppers and circular enclosures

- Ideal for custom installations that require magnetic separation, but lack space for a housing assembly

- Constructed from stainless steel and are standard in our Customary Grade finish

- Food Grade & Sanitary Grade finishes also available.

- Availalbe in Ceramic For small to large ferrous particle separation (nails, bolts, washers, etc.)

- Available in Rare Earth UHI-52™ used for "fine particle" separation such as metal filings, shavings, metal wear residue, work hardened stainless steel, etc.

RotoDrawer™ Magnets

- Motorized, cylindrical configuration of Rare Earth magnetic tubes on a horizontal plane that continually rotate through a gravity fed product stream

- Capture and remove ferrous tramp metal particles from vertical product flows

- Ideal for products with a tendency to bridge

- Powerful UHI-52™ (52 MgOe) Rare Earth Circuit for optimum reach-out & surface holding strength

- Food Grade Silicone Gasket Material

- 3/16” stainless steel housing and flanges

- Drawer and/or Guard Lock-Out

- SimpleClean™

- Self-Clean™

Pipe Magnet

- IMI’s Permanent Pipe Magnets protect processing equipment

- Improves product purity by capturing ferrous tramp metal contaminants in vertical flow systems

- Easy to clean

- All welded construction

- Stainless steel housing

- Fits 4” to 20” diameter pipe

- Door mounted permanent magnet

- Custom sizes and designs available

- Drilled 3/8” fl anges for easy bolt in installation

Spout Line Inspection Magnets

- SLIM™ Series Spout Line Inspection Magnets are used to find metal contamination sources PRIOR to the Process Stage

- The SLIM series is intended to be used in conjunction with a comprehensive foreign contamination program and should be strategically placed at several locations throughout the process stream, such as: discharge points of mixers, sifters, screws, etc., anywhere that product drops into a gravity spout.

- Features a 52 Grade Rare Earth Opti-B™ balanced circuit, featuring a high-performance blend of 9,500 gauss and 16.7 lbs. of pull strength on a 1/2” ball

Round Drawer-In-Housing Magnets

- In-stream magnet for dry, free flowing powders and granular products

- Magnetic separation is achieved with magnetic tubes assembled in a drawer

- Tubes are aligned on alternating centers for multiple row drawer configurations forcing the product flow in a zigzag pattern while contacting the magnetic tubes

- The cascade effect ensures maximum tramp metal separation by causing product to have repeated and intimate contact with magnetic tubes

- As ferrous metal enters the magnetic field, it is captured by the tubes and separated from the product flow

Gravity Magnets (Out-Stream)

GRAVITY FEED APPLICATIONS

MAGNETS OUTSIDE OF THE PRODUCT STREAM

Plate Magnets

- Designed for applications that have a tendency to bridge or plug a standard Drawer-In-Housing.

- Large 3" diameter tubes allow enough room for high volume product flows while capturing ferrous metal

- Ideal for flour, powdered sugar or moist products

- Powerful 52 MgOe Rare Earth Circuit

- BUNA Wiper Seals -for removing collected metal

- Compression Spring Assisted Seal Plate

- Stainless Steel Construction

- Food Grade EPDM Gasket Material - for leak resistant operation

Hump Magnets

- Designed for ferrous metal separation in dry processing systems

- Separation is achieved with magnetic tubes assembled in a drawer

- Tubes are aligned on alternating centers for multiple row drawer configurations forcing the product flow in a zig-zag pattern while contacting the magnetic tubes

- The cascade effect ensures maximum tramp metal separation by causing product to have repeated and intimate contact with the magnetic tubes

- Clean the tubes regularly to prevent build-up and wash-off of collected metal

Extractor & Split-Flow Magnets

- Delivers ferrous tramp metal separation in bins, chutes, drawers, hoppers and circular enclosures

- Ideal for custom installations that require magnetic separation, but lack space for a housing assembly

- Constructed from stainless steel and are standard in our Customary Grade finish

- Food Grade & Sanitary Grade finishes also available.

- Availalbe in Ceramic For small to large ferrous particle separation (nails, bolts, washers, etc.)

- Available in Rare Earth UHI-52™ used for "fine particle" separation such as metal filings, shavings, metal wear residue, work hardened stainless steel, etc.

Conveyor Line Magnets

Conveyor Line Magnets

MAGNETIC SEPARATION OF FERROUS METAL FOR BELT CONVEYED PRODUCTS

Magnetic Separation Pulleys

- Commonly Used as Head Pulleys in Conveyor System

- Occasionally Used as Magnetic Tail Pulleys

- Effective, Automatic and Continuous Removal of Tramp Metal from Material Flow

- Essential in Waste recovery, Feed & Grain and Mining Industries

- Removable Steel Shaft

- Stainless Steel Shell

- Powerful Permanent Magnet Circuit

- Shaft locking devices for shaft diameters up to 3”

- Straight hub with keyway and set screws for shaft diameters over 3”

- Axial magnetic circuit design

Drum Magnets

- Continuously Self-Cleaning Units

- Powerful Ceramic or Rare Earth Permanent Magnet Material

- Manually adjustable magnetic arc position

- Drum diameters from 12” to 24” available

- Drum Widths Available from 12” to 60”

- Inlet and Discharge Mounting Flanges

- Inlet transition to direct product flow

- Fixed diverter to separate cleaned product and collected tramp metal.

- Access Doors for Inspection and Drum Removal

- Sealed Bearings for Drum Support and Drive

Suspended Permanent Overhead

- Designed for separation of ferrous metal from a variety of over-the-belt conveyor applications.

- Delivers optimum operating efficiency with a continuous cleaning belt to keep the magnet face free of collected metal

- Compact design makes it ideal for use on portable size reduction equipment.

- Deep reaching magnetic circuits supply superior separation capabilities

- Use prior to a metal detector to achieve maximum separation and system performance capabilities

- Reclaims valuable ferrous metal

Suspended ElectroMagnet Overhead

- Designed for separation of ferrous metal from a variety of over-the-belt or cross belt conveyor applications

- Proven in industries such as Mining, Aggregate, Recycling, Tire Shredding, Foundry, Wood Chip, Pulp & Paper, Power Generation, Construction and Demolition.

- Designed to deliver peak ferrous metal separation and capture performance

- Self-Cleaning Suspended Electromagnet Separator

- Removes collected metal from the magnet face instantly and discharges it out of the product flow

- Continuous cleaning function

Pneumatic Line Magnets

Pneumatic Conveying APPLICATIONS

MAGNETS FOR PNEUMATIC LINE SYSTEMS

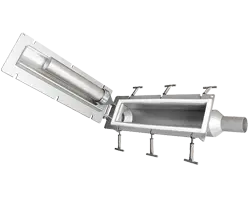

Pneumatic-Line Housing Magnets

- Ideal for dilute-phase pneumatic systems, the Pneumatic Housing is suitable for processing dry, powder, and granular materials

- Can be used ahead of processing equipment and bulk load-out stations to ensure product purity and protect machinery from tramp metal damage

- Incorporates a series of 1-in.-diam, 52 MgOe rare-earth tubes on staggered centers versus a single center-flow cartridge circuit often prescribed for pneumatic line systems

- This magnet's special configuration is engineered to ensure that all product flowing through the housing makes repeated contact with the magnets

- The metal extraction rate of ferrous and weakly magnetic stainless contaminants far exceeds any other magnetic separator available

Bullet® Magnets

- Ideal for dilute phase systems, typical Bullet® Magnet applications include: processing of powders, flour, chemical, resin, food stuff, pharmaceutical and mineral materials.

- Top Features: Leak-Resistant Seal, Easy Clean Stripper Collar, Door Mounted Magnet (removes magnet from product flow for cleaning) and Stainless Steel Construction

- Flow-thru design with aerodynamic stainless steel nose cone

- Can be installed anywhere in pneumatic line systems operating at or below 15 psi

- Ideal for use ahead of processing equipment and bulk load outs to assure product purity and protect machinery from tramp metal damage

- Helps extend the life of filters and screens

4JIT Vacuum Line Magnets

- The 4JIT magnet cartridge captures ferrous metal contaminates to provide equipment protection and improved product purity

- Clean captured metal by removing the clamp to separate the two halves. Once separated, wipe the metal off the magnet with a gloved hand or shop rag.

- Welded stainless steel construction with a one piece, stainless steel clamp

- Powerful Rare Earth UHI-52™ Magnetic Circuit

- Coupling ends are constructed of .065” wall tubing

- Viton, flange matched gasket material for leak-resistant operation

- Custom sizes, finishes and magnetic circuits

Exposed Pole Tube Magnets

- Designed for use in pneumatic line systems

- Leak-Resistant Seal and Stainless Steel Construction.

- Open flow design is ideal for use where product degradation is a concern

- Ideal for use in dense phase systems operating at or below 15 psi

- Typical installations include processing of pelletized plastics, foods, feed and grain or conveying of fibrous products or similar products that may have a high moisture content with a tendency to clog or congeal

- Ideal for use ahead of processing equipment and bulk load outs to assure product purity and protect machinery from tramp metal damage

- Cart mounted models available for truck and rail car bulk unloading

Email us at info@cmtnc.com or Fill Out the Contact Form Below