Bulk Bag Unloaders

Super Sack Unloaders and Bulk Bag Dispensers with Dust Control Technologies

The manufacturing process of foods, pharmaceuticals, chemicals, and other products often involves unloading raw material from bulks bags. The super sack unloading process often involves lumpy or densified material, material it extremely difficult to dispense. This often leads to plant operators attempting to manually extract the material from super sacks by shaking or hitting the bags, creating dust clouds and potentially putting the operators at risk. All of this can lead to disruptions in the manufacturing process, eventually hurting your bottom line.

CMT's Super Sack Unloader is designed to optimize the bulk bag discharging process by implementing various agitation methods while containing ambient dust in the Contain-It™ Chamber. Our Premier Super Sack Unloader offers dust-free bulk bag dispensing with guaranteed discharge of virtually any material. Our Super Sack Unloaders are offered in 3 Main Models: Short-Frame Model, Hoist-and-Trolley Model, and the Fork-Truck Loaded Model. There are two main types of agitation for increasing material flow: Massage-It™ Paddle Agitation (Ultra Heavy-Duty Pipe Agitators that move material into the Critical Flow Path) and Shape-It™ Vibration System (Shapes the Bulk Bag to the Steep Sloped Platform). Each Bulk Bag Dispenser model can be custom designed to fit your plant, and with your choice of features.

þ Customize Frame Dimensions

þ Customize Agitation Type

þ Customize/Integrate Outlet Equipment

þ Dust-Containment Access Chamber

þ Integral Hoist-&-Trolley Available

þ Bag Compactor Add-On Available

Super Sack Unloading Systems Overview

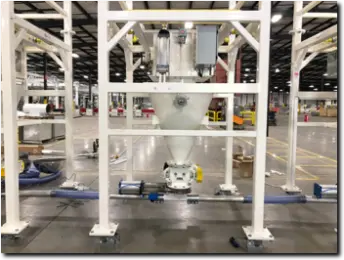

The Contain-It™ Access Chamber boasts a large and enclosed bulk bag handling area for the operator to tie and re-tie the bag with ease. The large bulk bag chamber is engineered to contain any accidental spills or dust that occurs from the super sack dispensing process. Custom matched to your downstream equipment: Hopper, feeder, rotary valve, slide gate, screw conveyor, pneumatic conveyor, etc. Inside the chamber, we offer the Close-It™ Super Sack Valve System that allows operators to close off and remove half empty bags, or to use as a batch control valve during the bulk bag unloading process. The Clamp-It™ Bulk Bag Spout Clamp provides an air actuated seal that lowers a stainless steel plate once the bag is in place, and secures the bag spout open in order to ensure proper material flow. It features 8” of vertical clearance to manipulate the bag spout, which compares to 2-4” for most competitors. No more knuckle busting! Additional features include: integrated Dust Collection System, Collapse-It™ Bulk Bag Evacuation System, and more.

Bulk Bag Support Frames

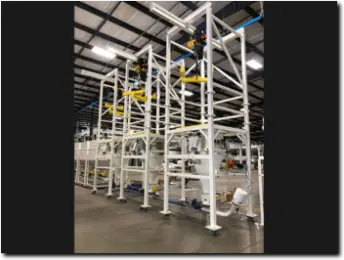

CMT Super Sack Unloader Systems are engineered to withstand demanding conditions in industrial applications. Our bulk bag unloaders are engineered and manufactured with a fully-welded supporting frame body, providing structural advantages over most bolted super sack unloader frames on the market. CMT offers three different heavy-duty frames: Hoist & Trolley Model, Fork-Truck Loaded Model, and the Short Frame Model (Ceiling Mounted Hoist & Trolley to Load).

Hoist & Trolley Model

The H&T Model features a 2-Ton Harrington Hoist and Motorized Trolley, in conjunction with a 4,000 lb capacity bulk bag hanger. This model is engineered with an upper frame and dual I-beams that are used to mount and support an 8” hoist and trolley I-Beam for increased stability. The main I-Beam features mechanical position stops at the front and back, ensuring the safe and correct position of the Trolley.Hoist & Trolley Model

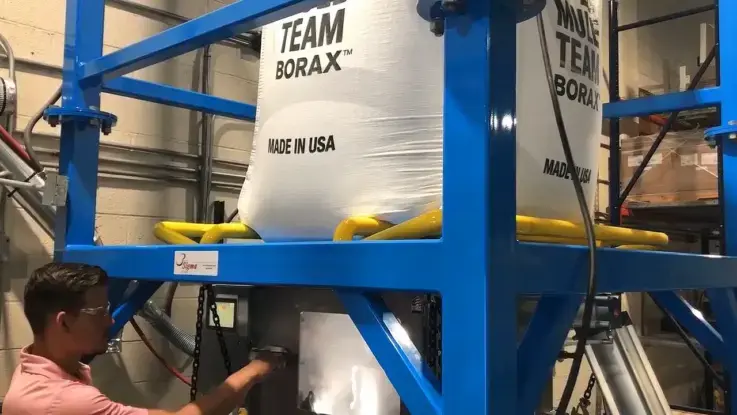

Fork-Truck Loaded Model

The Fork-Truck Loaded Model features a modular design that contains two "shelves" to support the bulk bag lifting frame. The lifting frame is designed with slots to fit most fork-trucks, but can also be customized to fit specific sizes and dimensions.

Fork-Truck Loaded Model

Short Frame Model

The Short Frame Model offers a space-saving bulk bag unloading option that is ideal for applications with limited ceiling height. No upper frame is provided, and this model employs a customer-provided, ceiling mounted Hoist &T rolley for the super sack loading process. Please note that Bulk Bag must be supported by the Hoist & Trolley at all times.

Short Frame Model

Super Sack Agitation Systems

When the properties of the material stored in bulk bags impede proper material flow, it can become extremely difficult to discharge the material from the super sack. This often leads factory workers and operators to "beat" the bags with sticks and other items in an effort to empty the material, often resulting in dangerous or hazardous conditions and accidents. 3Sigma's Agitation Technology was specially engineered to combat this problem, offering the industry's best material conditioning devices on the market. We offer multiple types of agitation systems that promote material flow, ensuring the safe and reliable unloading of materials.

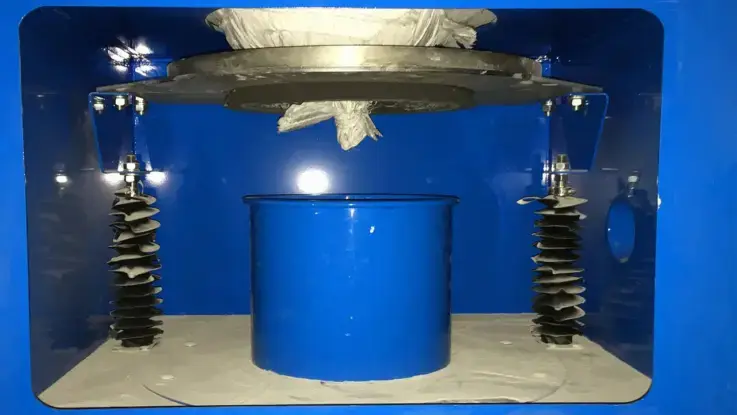

MASSAGE-IT™ DISCHARGE SYSTEM

Ultra-heavy duty pipe agitators move product into the critical flow path. Discharges difficult bulk materials. Massagers extend fully to 90-degrees. Guaranteed Discharge

Massage-IT™ Paddles

SHAPE-IT™ DISCHARGE SYSTEM

Ultra heavy duty, ¼” plate steel Shapes the Bulk Bag to the Steep Sloped Platform. No Exposed or Moving Parts. Controlled Vertical Vibration to Shape the bag and then Discharge.

Shape-IT™ Vibration

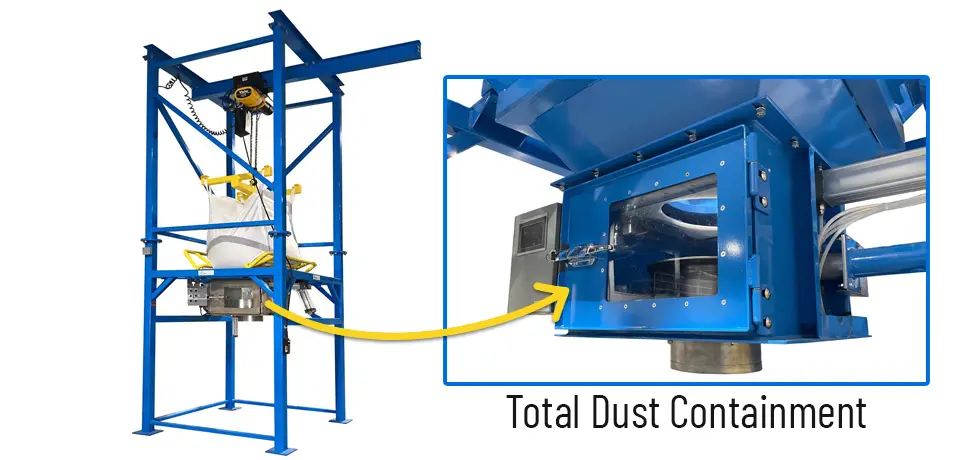

Contain-It™ Access Chamber

Contain Dust and Accidental Spills with the Largest Access Chamber on the Market

While we can minimize dust and spillage based upon the features we implement, the reality is, in almost all cases, material will be spilled, dust will get out of the bag, and cleanup will be required. The goal must be minimization. We have spent years designing and redesigning bulk bag unloaders to minimize these issues. At the end of the day, there will be some dust, some spillage. It CAN be minimal. The real question is, “Would you prefer to capture all spills INSIDE a LARGE Containment Chamber, with enough room to “collect it” or allow product to spill into your working environment?".

Spills Happen... CONTAIN-IT™

Spills BEFORE bulk bag unloading can occur.

Spills DURING bulk bag unloading can occur.

Operator Error is inevitable

Ensure the containment of spills and dust

CONTAIN-IT™ BAG ACCESS CHAMBER

- For bag access only – not product storage

- Large Access Chamber – 32” x 32” x 20”

- Large Viewing Window

- Tube-It™ Discharge Tube for basic spout seal

- Air actuated dust valve – opens/closes with door

- XL and XXL chambers are available

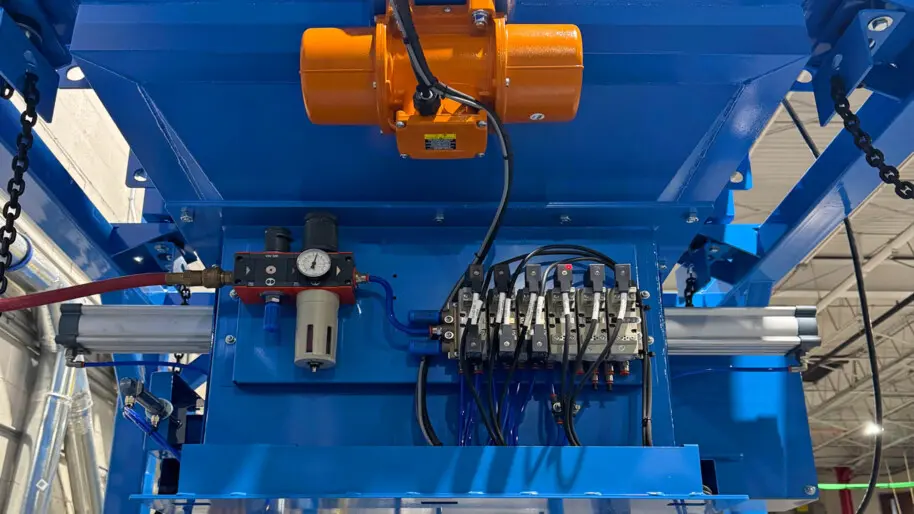

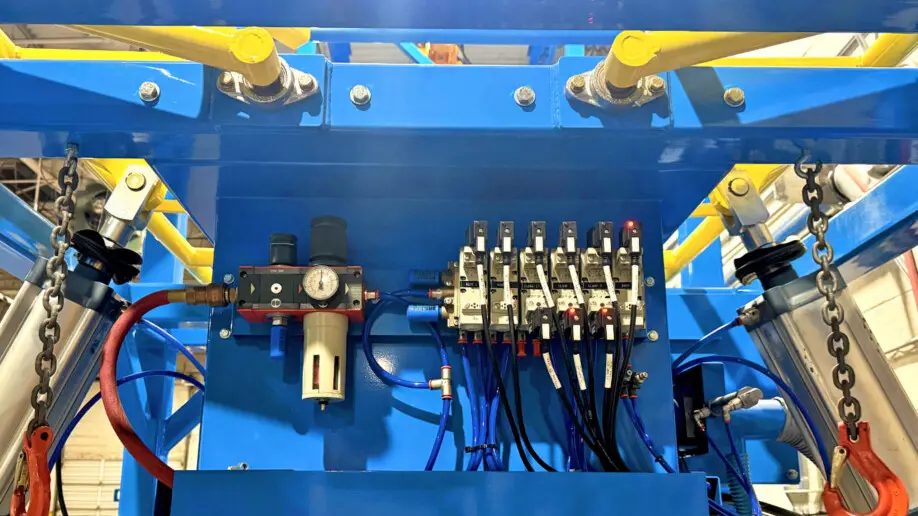

PRE-WIRED, PRE-PIPED SYSTEM

- All solenoids plumbed to all cylinders

- All solenoids wired to the BBU mounted control panel

- Air dump valve to dump all air in system for maintenance

- Client runs 110VAC to control, 80 PSI to F.R., 460 VAC to Hoist

Shape-It Bulk Bag Unloader units come pre-wired and pre-piped

Massage-It Bulk Bag Unloader units come pre-wired and pre-piped

Contain-It™ Access Chamber Options and Add-ons

TUBE-IT™ BAG SPOUT SEAL

The Tube-It directs discharged product from the bulk bag spout into the process through the sealed path.

Tube-IT™ Bag Spout Seal

CLAMP-IT™ BAG SPOUT CLAMP

The Clamp-It provides an air-actuated positive seal formed by clamping and pinching the bag spout open.

Clamp-It™ Bag Spout Clamp

SEAL-IT™ SPOUT ENCLOSURE SYSTEM

Seal-IT™ Spout Enclosure System

CLOSE-IT™ BAG SPOUT VALVING SYSTEM

To close off and remove half empty bags or to use as a batch control valve.

Close-IT™ Bag Spout Valve

VAC-IT™ DUST COLLECTION

Pull a negative across the containment chamber when opening the door to capture dust. Matched dust collectors provided.

Vac-IT™ Dust Collection

COLLAPSE-IT™ BAG EVACUATION SYSTEM

Use of dust collection, in combination with Clamp-It™, to evacuate and then collapse the empty bag.

Collapse-IT™ Bag Evacuation System

Integrated Industrial Solutions

Process-Integrated Super Sack UNLOADING Systems

Bulk bag unloaders (also called bulk bag dispensers or super sack unloaders) typically consist of a steel frame that supports the unloading of material from a FIBC super sack into the industrial process. However, not all bulk bag unloaders are created equal. We provide 3Sigma™ Bulk Bag Unloading Systems that make handling of super sacks practical and efficient by providing an easy and safe method to lift, support and discharge material. 3Sigma™ Bulk Bag Unloaders were specially engineered for dust-containment and ease-of-access for the operator. At CMT, we integrate design and integrate our super sack unloaders with other process handling equipment in order to provide controlled, regulated discharge with a variety of feed devices and weight control options.

General Customer Goals

- Dust-Free Bulk Bag Unloading.

- Discharge difficult/densified Products

- A Bulk Bag Discharger for Total Bulk Bag Discharging

- Minimal moving parts/ Minimal maintenance.

Super Sack Unloaders are typically implemented when capacity requirements dictate a change from 50 lb. bags to FIBC bulk bags, in order to save on material and labor costs. Understanding the properties of your material in the FIBC bags and setting your goals is a critical component to desigining your system. Many suppliers overlook the actual bulk bag and dive into offering you their standard bulk bag unloader – the “one size fits all” mentality. However, the properties of the Bulk Bag can impact the unloading process. Some items of concern include: Dimensions; Lined or Unlined; Loose Liner, Tabbed Liner or Glued Liner Flat Bottom or Cone Bottom; Single Trip or Multi-Trip; Bulk Bag Outlet Spout Dimensions; Bulk Bag coatings, etc.

Turn-Key Material Handling System for Large Composite Decking Company

"We Can Design and Provide Your Entire Process System, including Silos, Pneumatic Conveyors, Bulk Bag Unloaders, Feeders, Mixers, and More"

CMT's Industrial Bulk Bag Unloading Systems can integrate with your upstream and downstream equipment, improving your plant-wide process operations. Our Turn-Key Systems provide system-wide sensing, monitoring, and reporting, in order to bring you accurate, repeatable, and reliable results for your Industrial Conveying, Loading, Unloading, Weighing, and Feeding Systems for Bulk Powders, Granules, and Solids.

Bulk Bag Unloaders

Bag Dump Stations

IBC Systems

Feeding and Weighing

Mechanical Conveying

Pneumatic Conveying