Bolted Steel Storage Tanks

Industrial Bolted Tanks for Storage of Bulk Materials

Versatile and cost-effective silo storage systems for bulk solids.

Bolted tanks and silos are essential components in modern bulk material handling systems, delivering secure, efficient, and highly configurable storage for an extensive range of dry bulk solids. Engineered to protect materials such as cement, fly ash, grain, sugar, lime, plastics, and frac sand, they maintain product integrity by keeping contents dry, contamination-free, and ready for processing or distribution.

Designed for seamless system integration, bolted silos support multiple loading and discharge configurations, promote reliable flow through smooth-wall construction, and can be tailored for mass-flow or funnel-flow performance based on specific material characteristics.

þ Flanged Panel & Flat Panel Bolted

þ Dry Bulk Material Storage

þ Powders, Granules, Solids

þ Integrate with Pneumatic Conveying

þ Truck & Trailer Receiving/Loading

þ Flexible, Modular Construction

Features and Advantages

Overview of Dry Bulk Bolted Steel Storage Tanks

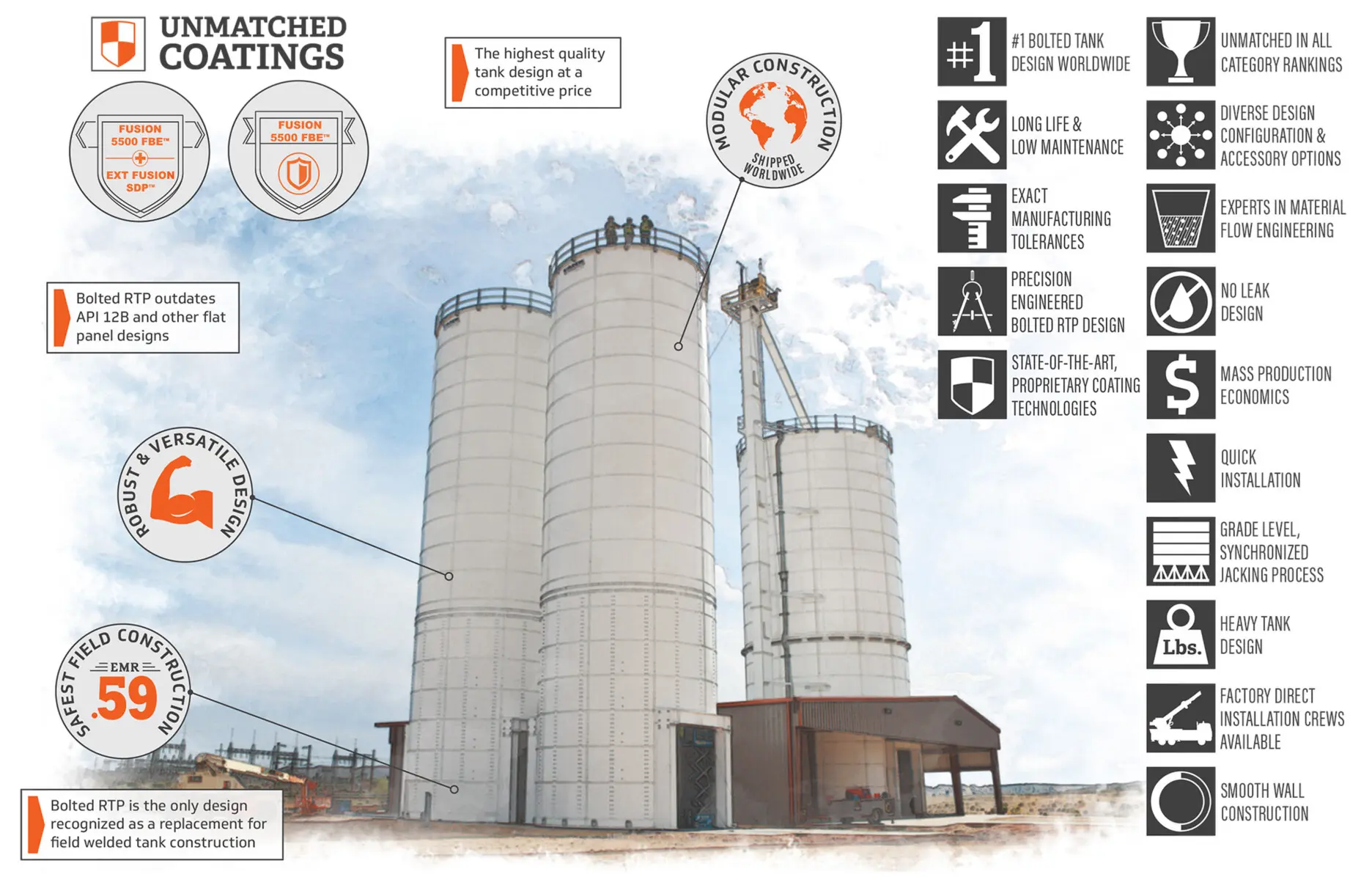

Dry bulk bolted steel storage tanks provided by CMT Process Solutions are precision-engineered, panelized silos designed for dependable storage and controlled handling of powders, granules, pellets, and other dry solid materials. Constructed from factory-fabricated steel panels that are bolted together on-site, these tanks provide outstanding structural strength, rapid installation, and broad adaptability across industrial applications.

Engineered Construction

CMT’s bolted steel tanks are fabricated from galvanized, epoxy-coated, stainless, or carbon steel panels that are precision-formed and seal-gasketed to ensure long-term, dust-tight performance. Their modular design enables economical transport and on-site assembly, even in locations where welded or concrete silos are impractical. Available configurations include flat-bottom, cone-bottom, skirted, and leg-supported designs, with hopper geometries engineered to promote optimal material flow.

Material Handling Performance

Designed to integrate seamlessly into modern bulk handling systems, CMT bolted tanks support:

- Flexible filling options: pneumatic, mechanical, or gravity feed

- Controlled discharge: screw feeders, rotary valves, slide gates, or pneumatic transfer systems

- Predictable flow characteristics: mass-flow or funnel-flow hoppers tailored to specific material properties

- Advanced flow-aid technologies: vibrators, air pads, fluidizing cones, and live-bottom reclaim systems for difficult materials

Smooth interior surfaces and carefully engineered hopper angles minimize bridging, ratholing, and particle segregation—ensuring consistent flow and dependable downstream performance.

Protection & Safety

CMT Process Solutions designs bolted tanks to safeguard product quality while meeting stringent safety and environmental requirements. Standard and optional features include:

- Weather-tight, corrosion-resistant construction

- Explosion vents, flameless vents, or suppression systems for combustible dust applications

- Sealed dust collection ports for clean, controlled ventilation

- Level sensing, overfill protection, and pressure/vacuum relief valves

- Optional insulation and exterior cladding for temperature-sensitive materials

Industry Applications

CMT dry bulk bolted steel tanks are used throughout a wide range of industries, including:

- Cement, fly ash, lime, and mineral processing

- Grain, feed, and agricultural storage

- Plastic resins, powders, and chemical additives

- Wood pellets, sawdust, chips, and biomass materials

- Frac sand and proppant handling

Their durability, reliability, and large-volume capacity make them ideal for manufacturing plants, transload facilities, energy producers, agricultural operations, and construction supply sites.

Key Advantages

- Rapid installation with minimal field welding or fabrication

- Modular expandability, allowing future height or capacity increases

- Lower total lifecycle cost compared to welded or concrete silos

- Simplified maintenance, with individual panel replacement capability

- Relocatable design for evolving plant layouts or mobile project needs

Email us at info@cmtnc.com or Fill Out the Contact Form Below