Shaftless Screw Conveyors

Shaftless Screw Conveyors

Shaftless Screw Conveyors

Shaftless Screw Conveyors to Efficiently Convey Bulk Materials for Various Industries

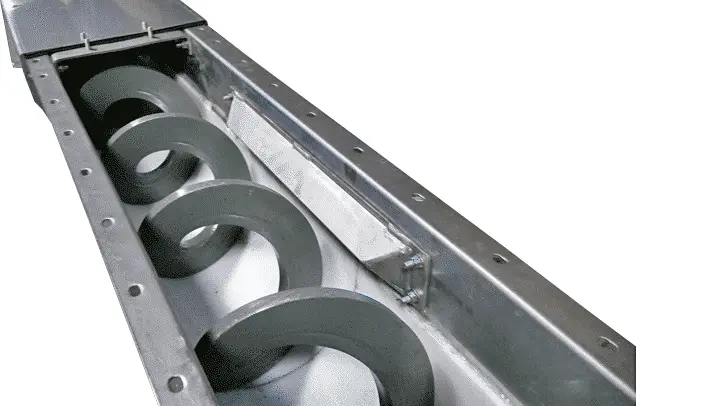

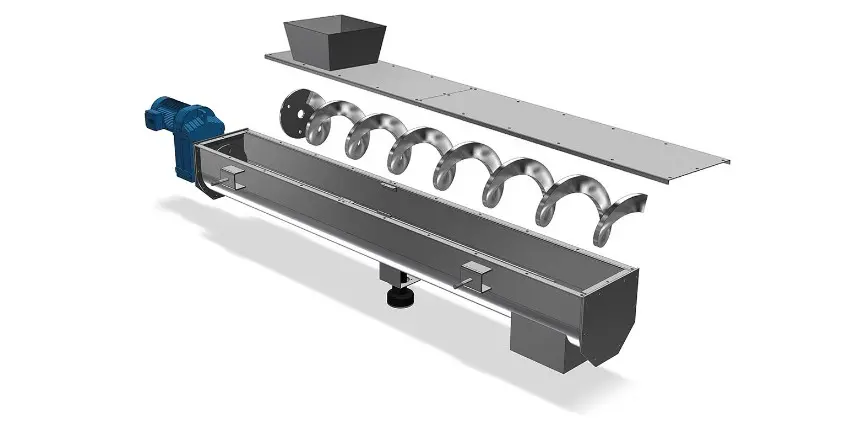

Shaftless Screw Conveyors are cost-effective solutions for transferring difficult-to-convey materials, including irregular shaped solids, abrasive powders, or semi-liquid and sticky materials . Shaftless Screw Conveyors have no center axis, requiring fewer parts than shafted screw conveyors, resulting in reduced maintenance costs. The shaftless design allows for higher trough loads at lower shaft rotational speed. The lack of inner shaft eliminates the typical blockages and material buildup that can accumulate on shafted screw conveyors, resulting in longer operating time, higher efficiency, and reduced maintenance. The shaftless design also prevents clogging on the surface, allowing sticky and abrasive materials to become easier to convey. Shaftless screw conveyors also eliminate pendants, hanging bushings and bearings, reducing the need for constant maintenance.

þ Sticky and Sluggish Powders and Ingredients

þ Improved Conveying Efficiency

þ Multiple Configurations for Flexible Factory Layout

þ Eliminates the Need for Internal Bearings

þ Carbon, Stainless, and Abrasion-Resistant Alloys

þ High Strength Alloy Spirals With Hardness Up To 350 BHN

Features and Advantages

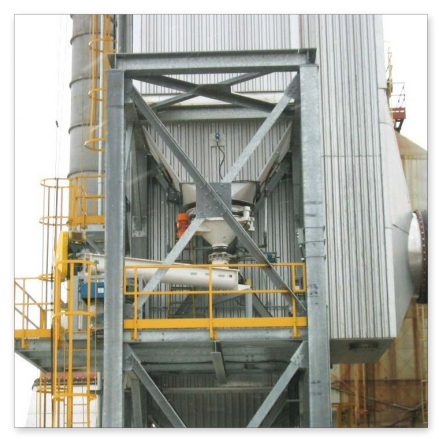

Shaftless Screw Conveyors meet the requirements of many industries, such as chemical, rendering, wood products and wastewater treatment. This type of conveyor efficiently conveys dry, semi-fluid or sticky materials. The shaftless design provides a nonclogging conveying surface by eliminating the need for intermediate shaft bearings. Engineered to require less parts than the shafted screw conveyor, the shaftless auger reduces capital cost and overall maintenance costs. Better performance is achieved through zero-clearance between the trough and spiral. This improves conveying efficiency and eliminates many of the flow-impeding issues common with shafted screw conveyors. Higher trough loading allows for lower operating speeds. Another advantage of the Shaftless Screw Conveyor design is that it allows for greater flexibility and efficiency in factory layout, providing for end-to-end, side inlet/discharge and vertical configurations.

Advantages of Shaftless Screw Conveyors

- Better Performance – Zero-clearance between trough and spiral improves conveying efficiency

- Greater Flexibility – Direct transitions between equipment provide simplified plant layout

- Lower Operation Costs – Fewer components require maintenance and replacement

- Higher Trough Loading – Higher conveying capacities are achieved at lower operating speeds

Available Features/Options

- Spirals: High Strength Micro Alloy 350 BHN, 304/316 Stainless Steel, Nitronic, Hastelloy

- Housings: CEMA Standard U-Trough or Tubular Housing

- Liner Materials: UHMW, Xylethon and Abrasion-Resistant Steels

- Shaft Seals: Split Flanged Gland Seal with Multiple Rings of Packing

- Drive Shafts: KWS One-Piece Flanged Drive Shaft

- Spiral Hold-Downs: Over Center or Side-Angle Removable

- Covers: Flanged Covers with Bolts or Clamps and Hinges

Photos

Email us at info@cmtnc.com or Fill Out the Contact Form Below