Hammertek SMART ELBOWS®

Hammertek SMART ELBOW® Deflection Elbows for Pneumatic Conveying Systems

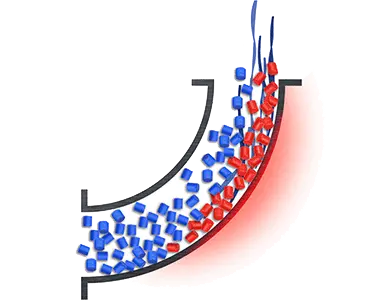

Reduce wear in your pneumatic conveying lines with HammerTek® Corporation's SMART ELBOW® Deflection Elbow. The HammerTek Smart Elbow’s design uses a spherical chamber slightly beyond the 90° or 45° turn that creates a rotating ball of material suspended in the air that allows the chamber to capture a portion of the airflow traveling through the line and cause it to double back into the material stream, creating a deflection zone that eliminates elbow wear and product degradation. The deflection-action of the Smart Elbow can increase the lifespan of your pneumatic conveying system by several years. Contact one of our CMT process engineers for a quote or free consultation if you have questions regarding your pneumatic conveying line.

Applications and Markets Served:

- Abrasives- Materials conveyed include foundry sand, limestone, fly ash, fiberglass, grit, cement and other aggregates

- Plastics- Materials conveyed include Polypropylene, Polyethylene, PVC, HDPE, LDPE, PET, PTFE, Nylon, and Styrene

- Grains- Materials conveyed include soybean, corn, wheat, rye, rice, oats and barley

- Power- Materials conveyed include limestone, fly ash and Magnesium Oxide

- Pulp & Paper- Materials conveyed include Hog fuel, wood bark, and saw dust

- Water Treatment-Materials conveyed include limestone

All Images and Videos Courtesy of the HammerTek Corporation

Features and Advantages

Benefits of the Hammertek Smart Elbow

Hammertek® Elbow Pneumatic Conveying Line Fittings

Reduction in Elbow Wear, Material Degradation, and Installation Space

Wear is one of the most common problems in pneumatic conveying systems. It is a problem that can cost tremendous amounts of resources in labor and replacement costs. Wear creates issues like elbow failure, formation of streamers, breakage, and dusting of fragile materials, and plugging and build-up. Our Process Engineers know that installing a HammerTek Smart Elbow instead of a conventional elbow can prevent many headaches and lead to a durable process system that ensures the quality of the end-product. The Smart Elbow design features a spherical chamber that protrudes partially beyond the desired 90° or 45° pathway, causing a ball of material suspended in air to rotate, gently deflecting

incoming material around the bend without impacting the elbow wall or generating heat. This simple, yet brilliant discovery was observed to cause material to rotate in the same direction as the airstream that powers it, which causes incoming material to be cushioned by the ball's rotation, and is gently deflected around the bend. The HammerTek Smart Elbow prevents impact with the elbow wall, essentially eliminating costly elbow wear, material degradation, melting and plugging. . The tight-radius Smart Elbow design requires roughly one-half to one-tenth the space needed to accommodate long-sweep elbows of equivalent diameter. This helps reduce space requirements in new installations and reclaim space in retrofit applications.

Minimal degradation aids dust control

The design of the Smart Elbow indirectly reduces dust by preserving product integrity and preventing material impact. Many plant managers have witnessed the benefits of the dust control that the Smart Elbow provides, noticing significantly less overall dust in their system. Smart Elbows provide better flow of material, resulting in less aeration and less dust as the product is conveyed out of the pneumatic line and into the next part of the process. This is a great advantage in applications with extremely dusty materials.

Reduction in Offload Times of Bulk Materials

Transfer times are an important measure of design efficiency in any dilute-phase pneumatic transport system, particularly when offloading bulk materials from trucks or railcars into storage silos. The Smart Elbow design decreases aeration and increases density, reducing the time a transport driver must wait for materials to settle as the silo fills up. Several Hammertek customers report improving their offloading times by up to 50% with the deflection elbow design vs. long-radius sweep elbows.

Improved Environmental and Safety Performance

The increase in durability and reduction of overall dust generated by the system has several environmental and safety performance factors. By significantly reducing the likelihood of an elbow wear-through, the risk of creating a polluting situation where bulk powder can escape from the system and increase employee exposure is minimalized. Generating less dust in the system through the implementation of the Smart Elbow also reduces the likelihood of dust collection filters clogging and causing a safety valve to release material into the atmosphere. Decreasing the load on filter media additionally minimizes the risk of a safety valve malfunction that could result in an over-pressurized dust collector being launched from its mounting.

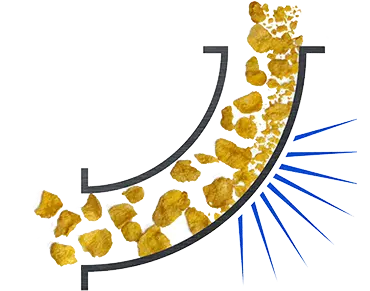

3 - PREVENT Breakage

Smart Elbows PREVENT breakage and dusting of fragile materials, such as corn flakes.

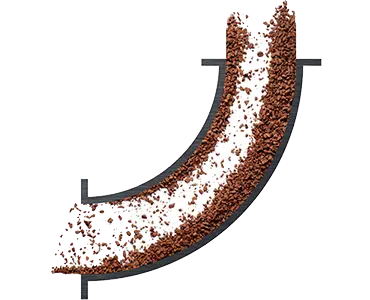

4 - PREVENT Plugging

Smart Elbows PREVENT plugging and build-up of cohesive and sticky powders and solids

1 - PREVENT Wear and Failure

Smart Elbows PREVENT wear and failure when conveying abrasives and mineral-based powders

2 - PREVENT Streamers

Smart Elbows PREVENT the formation of streamers and angel hair commonly found in plastics applications

Images courtesy of the HammerTek Corporation

Hammertek SMART Elbow Options

- Pneumatic Conveying Elbow Alloy Materials

- Aluminum

- Cast Iron

- Ductile Hard

- HammerLast 400

- HammerLast 500

- HammerLoy

- 304 Stainless Steel

- 316 Stainless Steel

- Carbon Steel

- Pneumatic Conveying Elbow Tube sizes

- 90 degree HammerTek Smart Elbow Schedule 10/40 & 80 from 1 ½” to 18” dia.

- 45 degree HammerTek Smart ElbowSchedule 10/40 & 80 from 1 ½” to 16” dia.

- 90 degree HammerTek Tube Size 11 gauge 1 ½” to 8”

- 45 degree HammerTek Tube Size 11 gauge 2” to 8”

- Special Coatings

- Virtually eliminates wear from pneumatic conveying abrasion

- Eliminates pneumatically generated streamers and fines

- Reduces product degradation of friable materials

- Eliminates plugging and surging

- Reduces heat from friction

- Space savings, 60% less space compared to Long Radius Sweeps

- Reduced maintenance cost

- Eliminates unscheduled plant shutdowns

- Ease of installation with flanged or socket weld

- No increase in pressure drop across entire system

- Self flushing prevents cross contamination

Email us at info@cmtnc.com or Fill Out the Contact Form Below